SCAF-TECH LEADS WITH INGENUITY, LAYHER MATERIALS TO REALIZE TORONTO’S NEW MIXED-USE SPACE

SCAF-TECH LEADS WITH INGENUITY, LAYHER MATERIALS TO REALIZE TORONTO’S NEW MIXED-USE SPACE

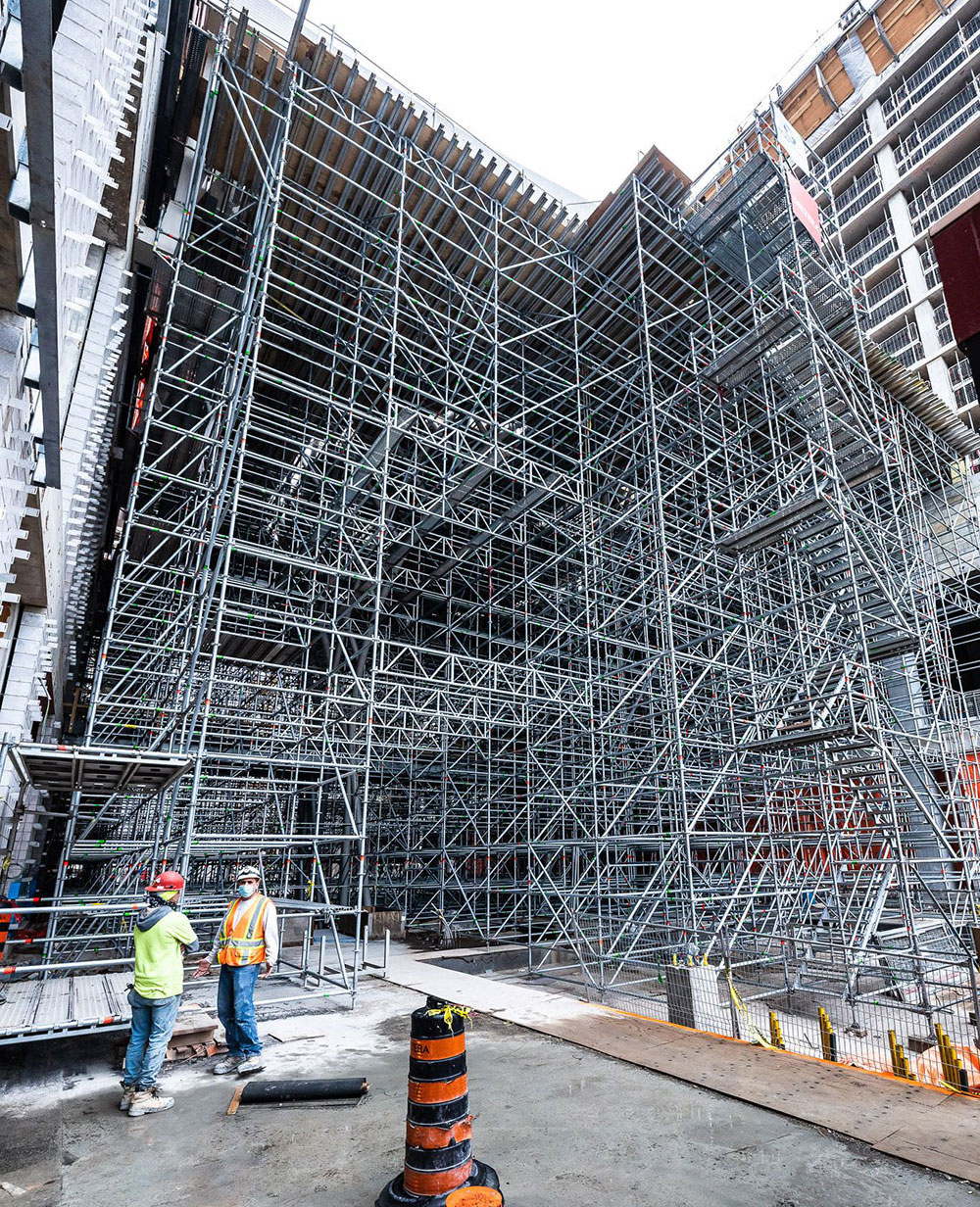

Toronto – Scaf-Tech recently facilitated the completion of The Well, an ambitious mixed-use space, combining Layher Allround with scaffolding innovation to make the project’s jewel – a 35,000 square foot glass canopy – a reality.

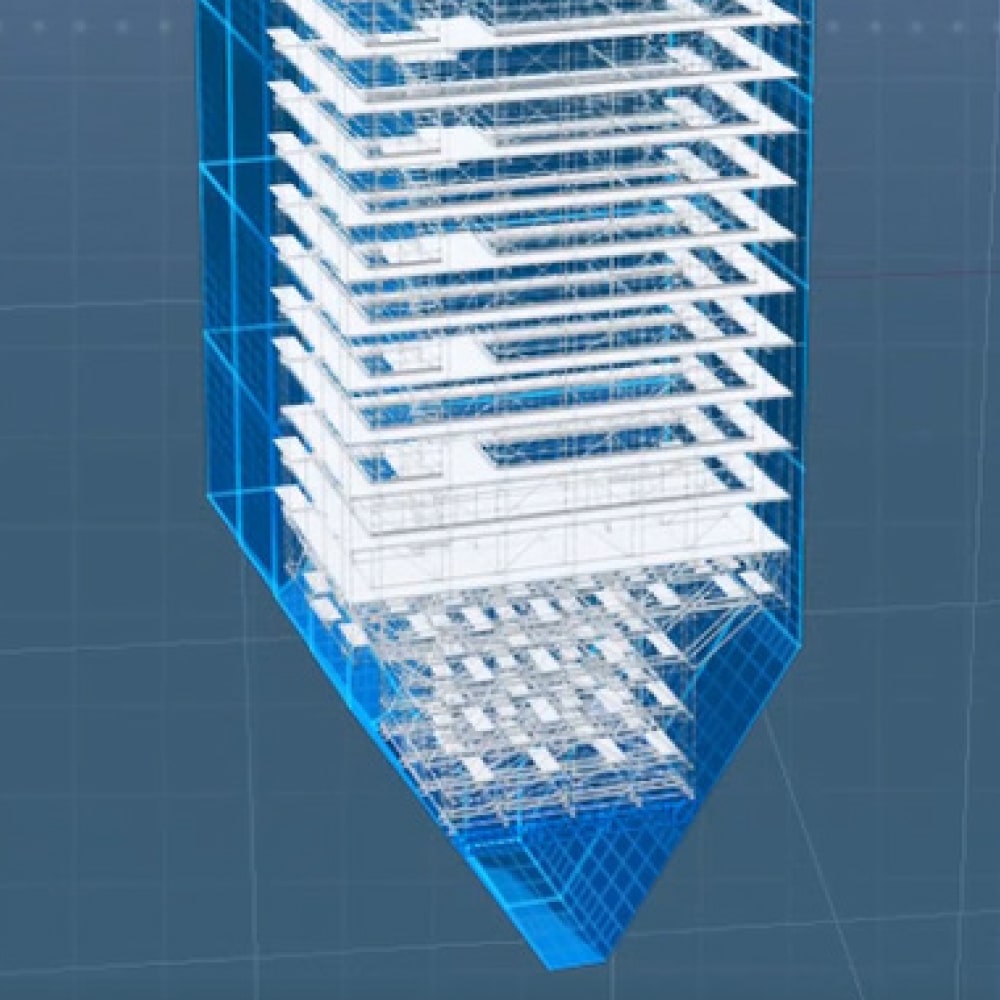

When fully operational, The Well will include 1.2 million square feet (sq ft) of office space, 320,000 sq ft of retail and food services, and 1,700 residential units spread over 7.7 acres, according to the official website. It is located between Front Street, Spadina Avenue, and Wellington Street West in the King West area.

PROJECT CHALLENGES

PROJECT CHALLENGES

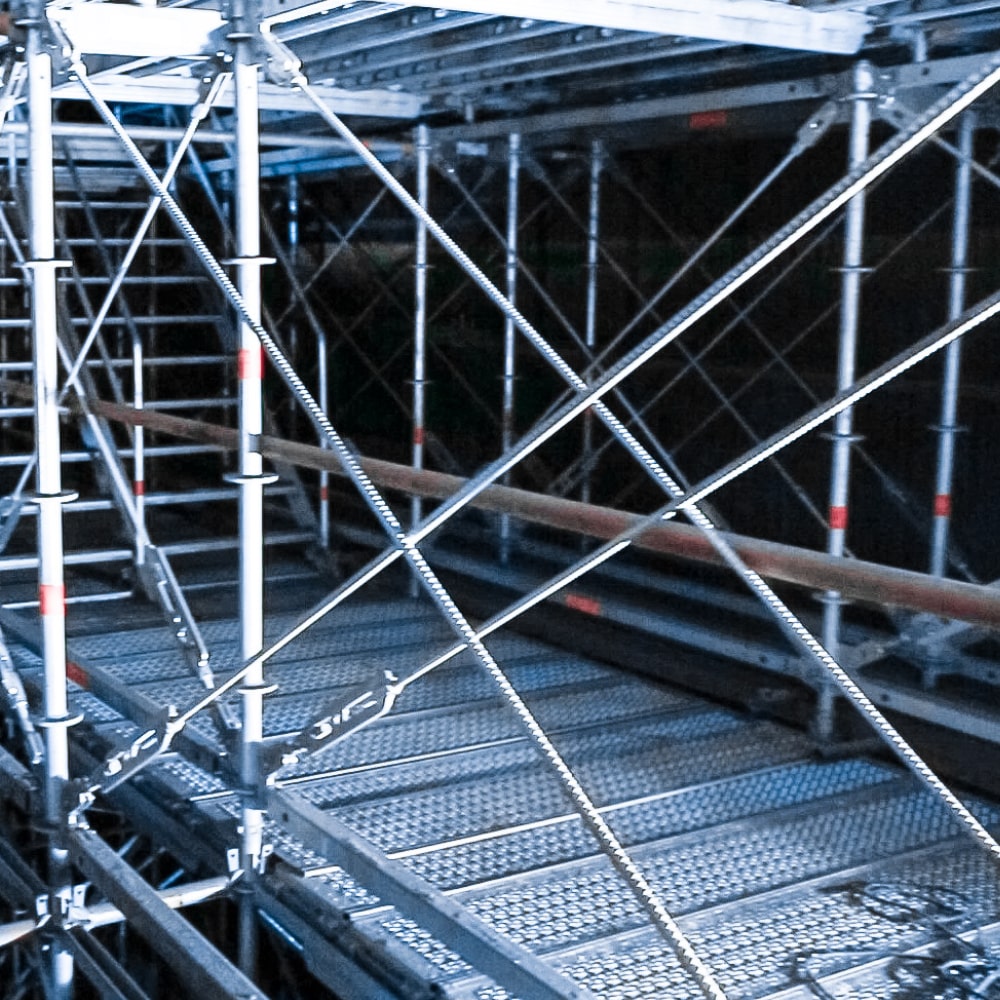

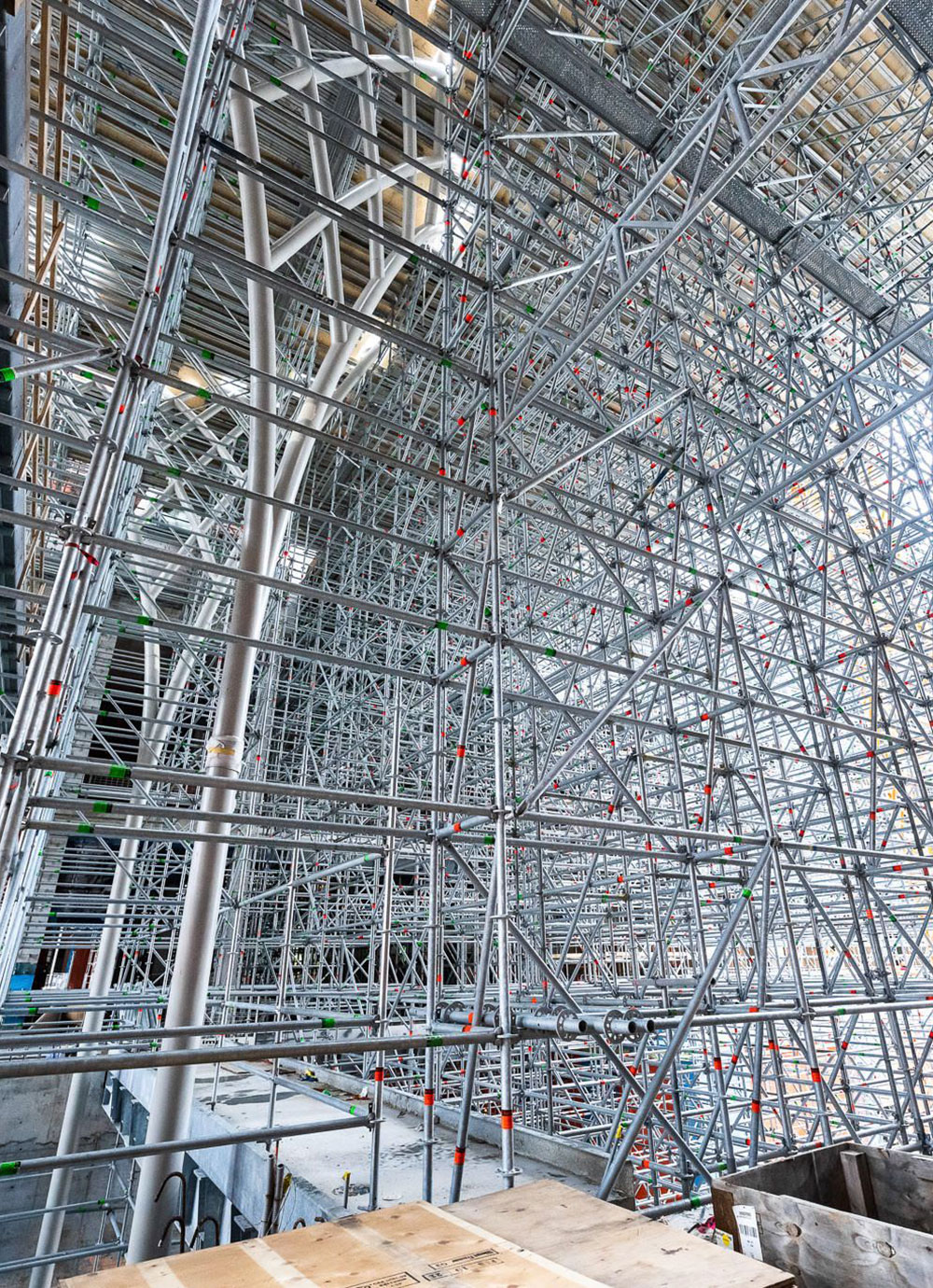

The approximately 2,000-glass-panel canopy covering the galleria spans multiple buildings to provide shelter, light, and ventilation to the space below.

Its construction posed a significant challenge because surrounding buildings provided limited space for assembly and disassembly of scaffolding and, once completed, the canopy itself would render overhead space inaccessible with large equipment.

“It was like taking a ship out of a bottle,” said David Hannah, co-founder of Scaf-Tech who began planning in early 2019 alongside co-owner Rick Henderson and Uzzo Calderaro, CEO and cofounder.

Additionally, the scaffold needed to provide accessibility to multiple trades performing work to building facades. “We had the forming teams talking about the buildings, the electrical team, the steel team, everyone talked about what they needed,” said Hannah.

THE DESIGN

THE DESIGN

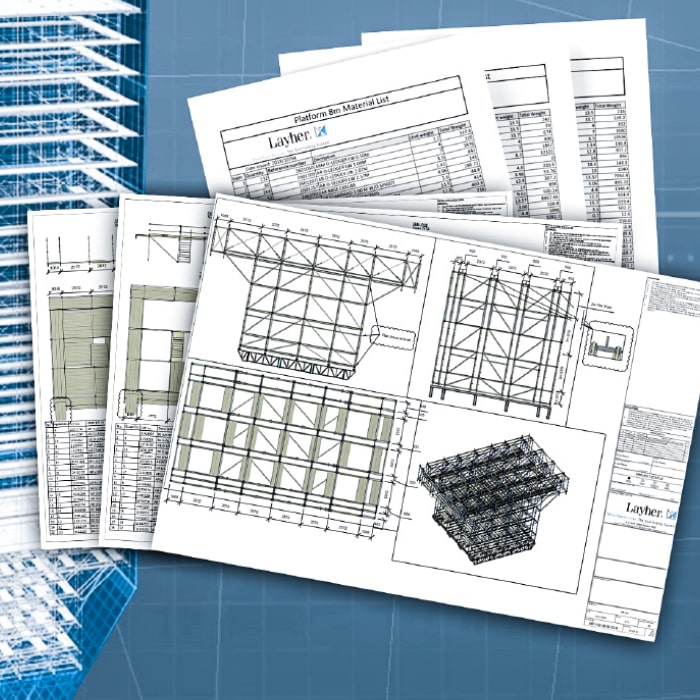

Scaf-Tech worked with internal designers in addition to Layher engineers and the AJW design firm to draft the design. The team weighed a number of options, including scissor lifts for mobile platforms and steel girders before settling on access platforms.

“At the initial stage, everything was on the table,” said Hannah.” The final design ended up being a more traditional scaffold because it needed to be cost effective, flexible, quick to install and dismantle.”

“There are a lot of really creative custom solutions but what Allround scaffolding and Layher brought to the table that steel girders don’t is that the scaffolding is reusable.”

This was particularly important because the structure progressed with the work. Once installation was complete on one portion of the canopy, dismantle would begin, with the same equipment used to build track for the job ahead.

Tangible results driven from intense innovation in design, engineering and safety

FLEXIBILITY

FLEXIBILITY

Because multiple trades used the platform to complete their portion of the work, flexibility and communication were crucial.

The team went through five design iterations throughout the process.

“The Allround allowed us to be making modifications to allow additional access or remove portions to fly equipment in and out,” said Hannah. “It was a measure of flexibility that other solutions didn’t provide.”

This was additionally advantages because custom parts quickly eat into project costs, and bringing in special equipment inevitably requires additional time to exit the job site. The Allround provided cost and time savings by eliminating the need for custom parts and simplifying dismantle.

LOGISTICS

LOGISTICS

To meet project needs, Scaf-Tech employed a cast and crew of 30 workers working full time over the course of 18 months. Disassembly was done by hand, with workers forming a chain to pass material from the top down.

“Although it was labor intensive, we were able to make it very repeatable,” said Hannah. With the current labor market, we knew we were going to be dealing with a lot of new scaffolders, but the Layher product is easy to handle and figure out.”

Ryan Freedman, Sales Manager at Layher Scaffolding, facilitated the arrival of scaffolding components over the course of the project, coordinating shipments as needed. “Logistics is key,” said Freedman. “A lot of coordination happens around worksites, what can go to the site when, and how much.”

MATERIALS

MATERIALS

Scaf-Tech utilized Allround Scaffolding and the System Stair Tower by Layher.

The Layher Allround

The Layher Allround is the industry standard for modular scaffolding, offering unbeatable adaptability with superior quality and unparalleled assembly speed. The Allround features eight connections at various angles with lightweight construction that helps transport the system effortlessly. The powerful tensile steel construction ensures unmatched reliability and safety thanks to the AutoLock function.

Allround Stairway Tower 200

Layher’s most utilized stringer access stair, constructed using standard Layher Allround® components. With the Allround® stairtower 200, 10-standard, each stairway is assembled from 2 separate O-stair stringers 200, with standard decks used as steps. The high proportions of standardized material in addition to the low weight/volume of the individual parts permits a lot of variants in the stairway width while keeping the additional costs low.

THE TEAM

THE TEAM

Scaf-Tech was established in 2008 in the Greater Toronto Area and specializes in scaffolding services, scaffold equipment, and labor for industrial, institutional, and commercial applications. David Hannah and Uzzo Calderaro are cofounders with Uzzo serving as CEO; Rick Henderson is co-owner.

Layher Scaffolding is a leading scaffolding manufacturer worldwide, offering superior industrial and commercial scaffolding systems and solutions. Ryan Freedman is the Layher Branch Manager of Eastern Canada operating from the Greater Toronto Area.

Layher and Scaf-Tech have worked together on multiple projects since 2009.

Other key players included Joseph Gartner, of the Permasteel Group, who manufactured and designed the canopy and shipped it from Germany.

Bass Installation assembled the canopy upon arrival and installed the retractable glass walls of the marketplace below.

Deltera was responsible for the commercial builds, and Ellis Don for the office building.

Scaf-Tech’s scaffolding portion of The Well was completed in September of 2022.