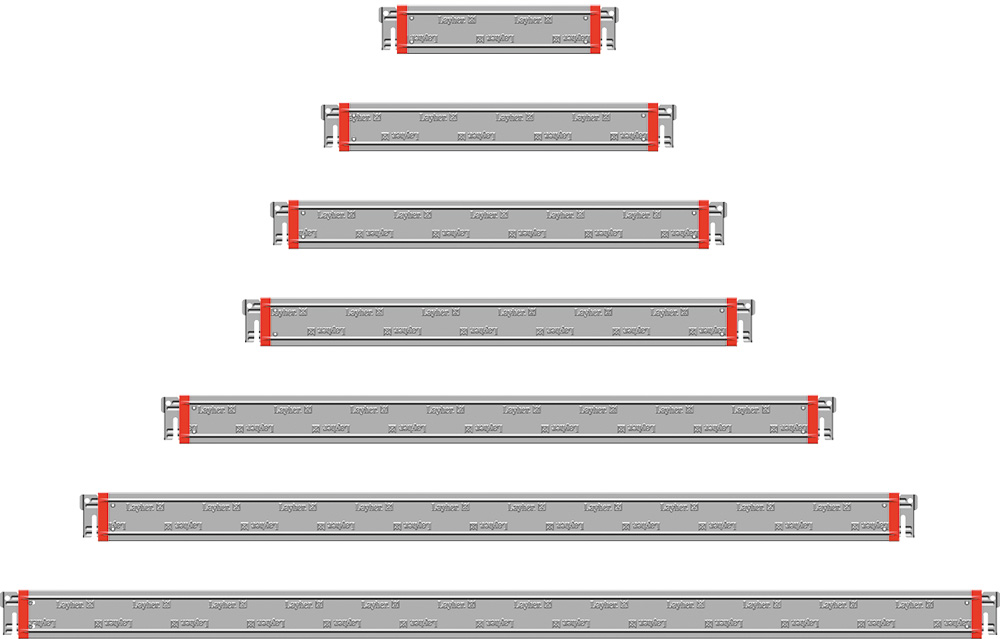

INDUSTRIAL STEEL TOE BOARDS

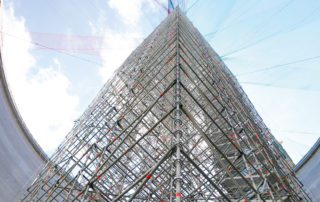

Layher Industrial

Steel Toe Boards

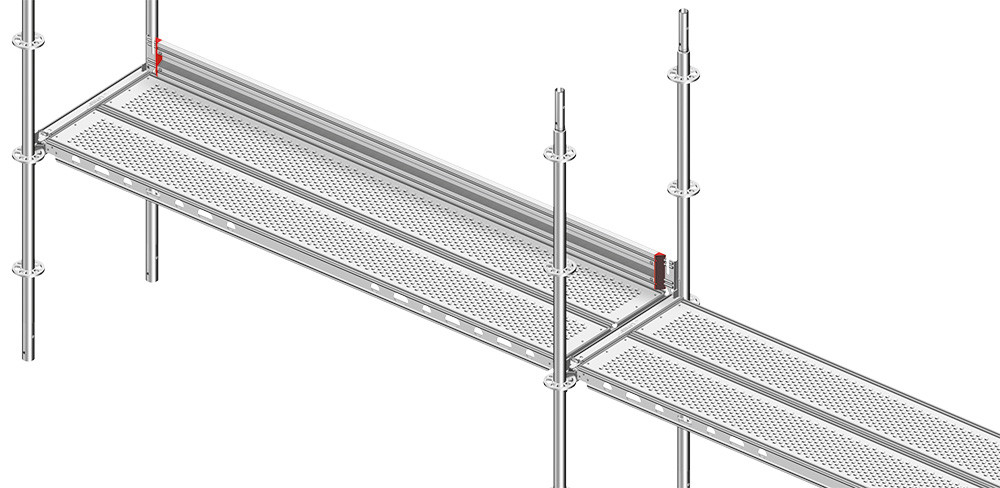

STEEL TOE BOARDS

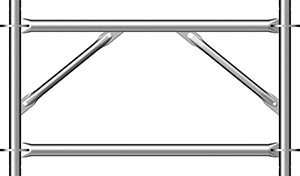

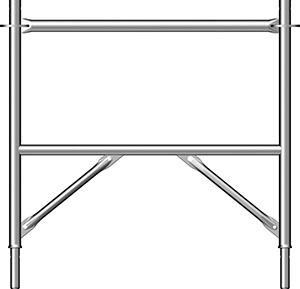

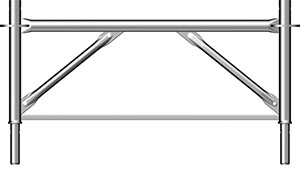

In very windy conditions or critical areas it can sometimes be necessary to secure toe-boards from lifting.

Advantages

- Reduction of fire risk

- High stiffness and sturdiness

- Easy stacking of the toe boards

- No gap between toe board and deck

Toe Board Clamp

Note

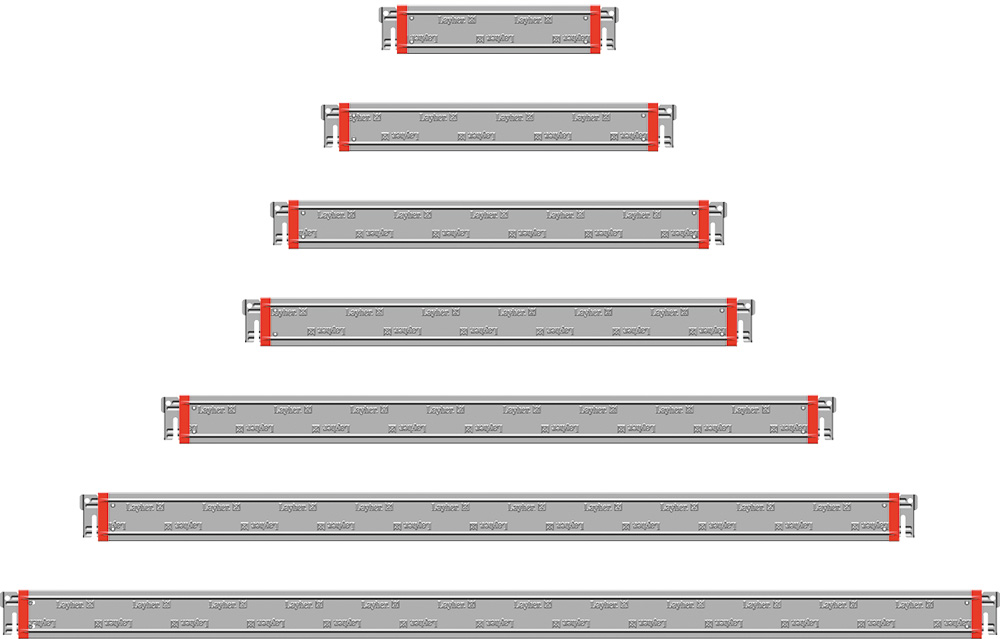

- Available in all sizes

Accessories

- Optional toe board clamp

STEEL TOE BOARDS

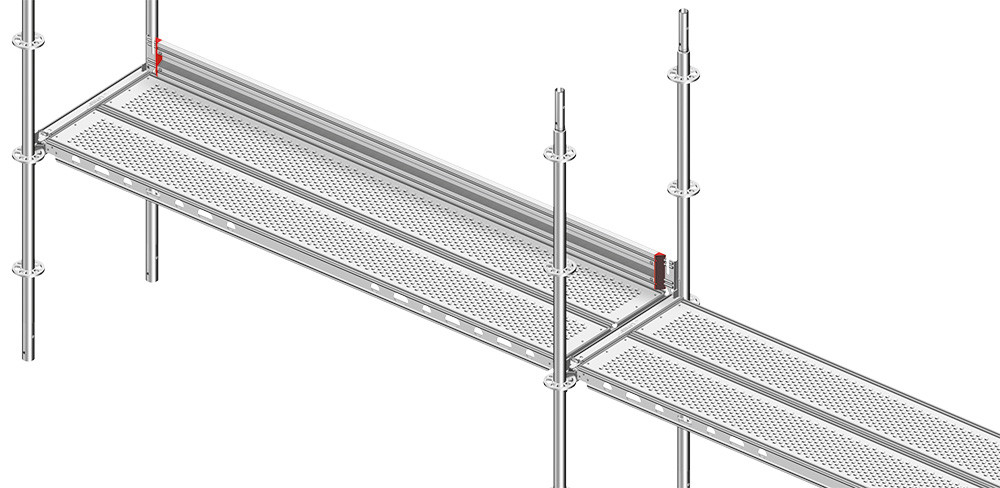

In very windy conditions or critical areas it can sometimes be necessary to secure toe-boards from lifting.

Toe Board Clamp

Advantages

- Reduction of fire risk

- High stiffness and sturdiness

- Easy stacking of the toe boards

- No gap between toe board and deck

Note

- Available in all sizes

Accessories

- Optional toe board clamp