STURDY. STRONG. LIGHTWEIGHT.

STURDY. STRONG. LIGHTWEIGHT.

A good product is now even better! This is exactly what’s been achieved with the Steel Deck Lightweight (LW). By using higher-tensile steel grades, thinner material, and an intelligent combination of profiles and material concentrations at structurally relevant areas, it has proved possible to reduce the weight of the steel deck, already established in the market, while retaining its high load-bearing capacity. That makes this steel deck lighter, handier, and more effective. Discover the benefits that the Steel Deck LW from Layher has to offer.

The Latest Product in the Layher Lightweight Family is Distinguished By:

- Cut Weight, Boost Speed: Enjoy up to 10% weight reduction without sacrificing strength, accelerating assembly, and slashing labor costs.

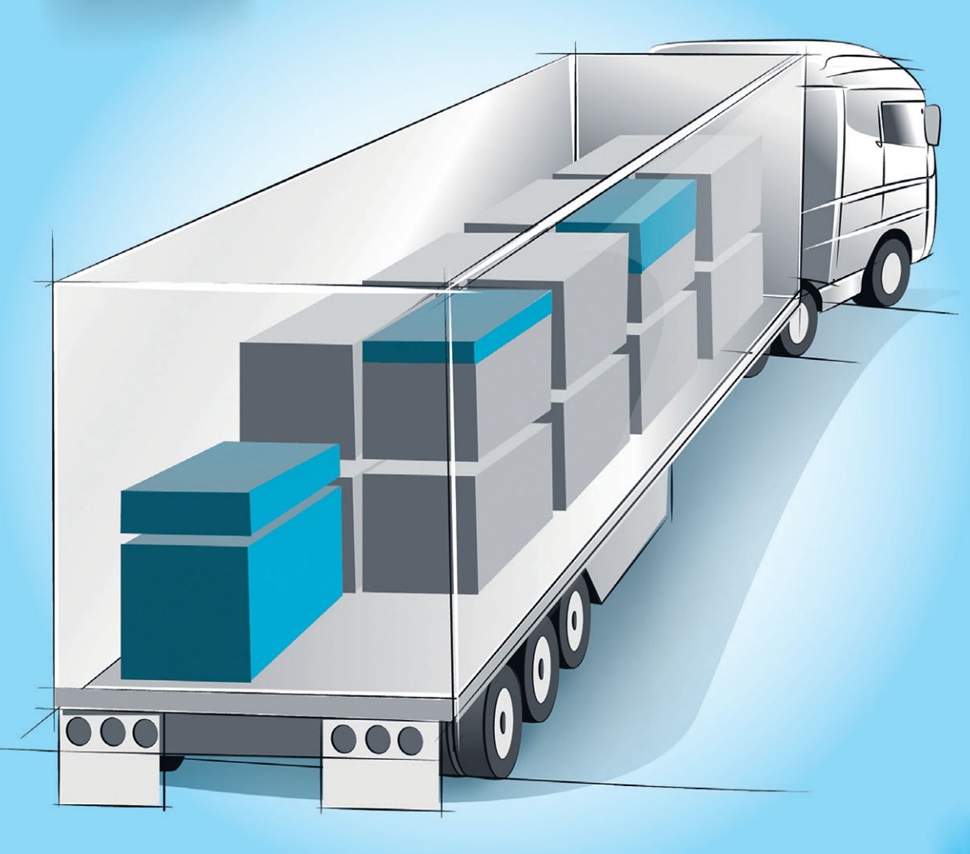

- Maximize Transport Efficiency: Optimize truck space with our lightweight decks, enhancing logistical efficiency and minimizing overheads.

- Built with Safety in Mind: Walk confidently on reinforced decks, ensuring stability and security with every step.

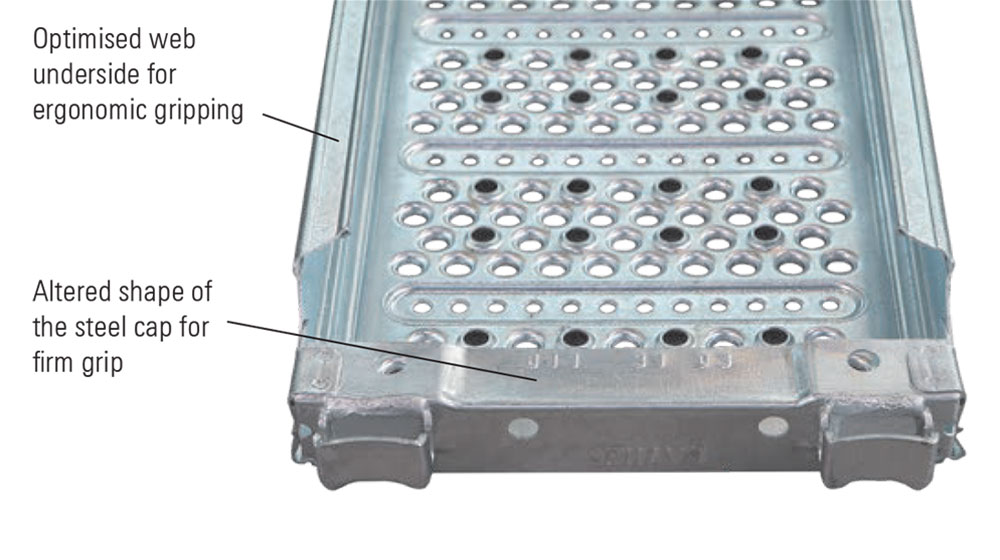

- Enhanced Handling: Thanks to optimized steel caps and profiles, the grip is easy to use, ensuring smooth operations in any environment.

- Seamless Integration: Upgrade effortlessly with compatibility across generations of Layher steel decks, ensuring a smooth transition to enhanced performance.

NEW! LAYHER Steel Deck Lightweight

Lighter, Faster, Safer

NEW! LAYHER Steel Deck Lightweight

Lighter, Faster, Safer

Layher’s Steel Deck Lightweight is 10% lighter yet maintains strength. This translates to faster assembly, improved ergonomics, and increased profitability. It integrates seamlessly with existing decks for a safe and efficient scaffolding solution.

THE BENEFITS OF LAYHER LIGHTWEIGHT

THE BENEFITS OF LAYHER LIGHTWEIGHT

- Lower weight

- Enhanced load-bearing capacity

- Improved safety

- Fully compatible with Layher Allround components

- Time-saving construction site erection and dismantling

- Cost savings through approximately 10% higher productivity

- Approximately 12% increase in truck payload by volume

PRACTICALLY-MINDED SAFETY

PRACTICALLY-MINDED SAFETY

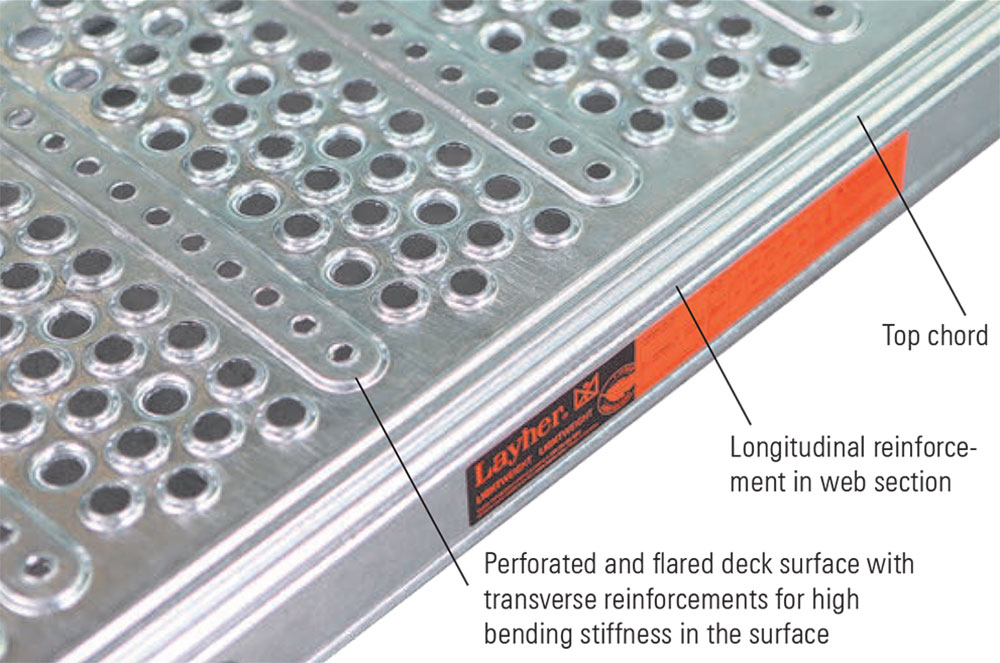

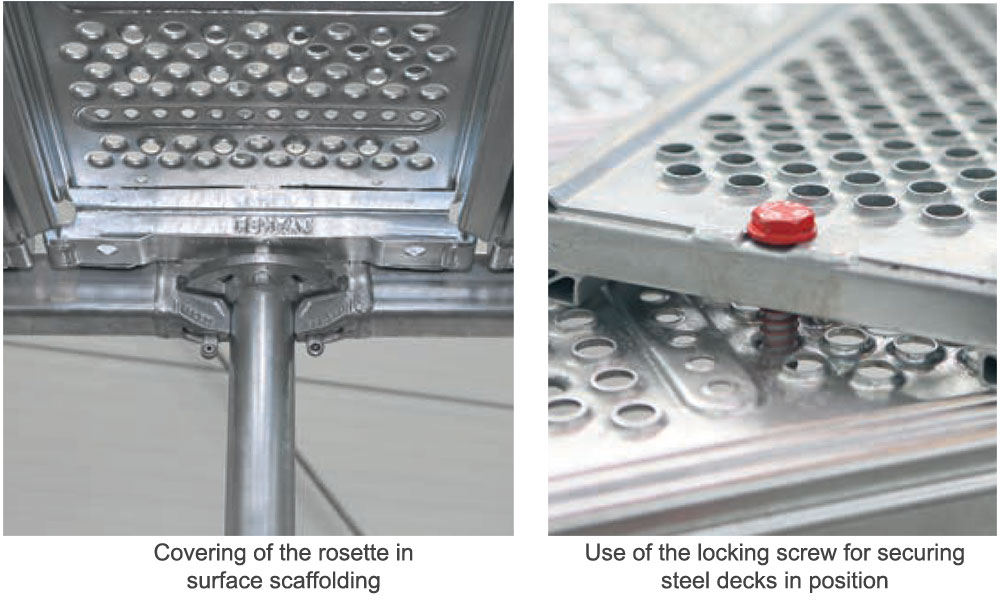

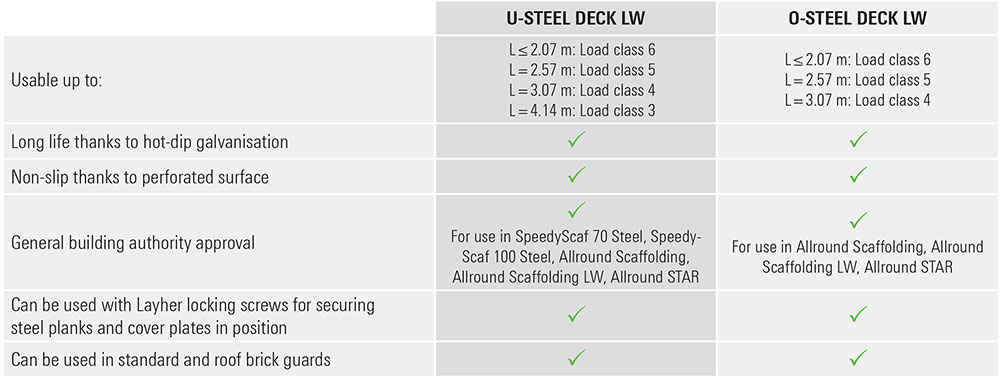

Despite a lower weight, the high load-bearing capacities of the proven Layher steel deck remain unchanged. This is achieved by transverse reinforcements on the deck surface and longitudinal reinforcements on the web section. Also, the cross-section of the deck was optimized structurally by locating material concentrations in structurally relevant areas. The transverse reinforcements and the typical flared perforations on the surface also create a strong feeling of safety when walking on the deck. In addition, the longitudinal reinforcement provides optimum transmission of lashing forces during transport.

The Steel Deck LW can, just like previous generations, be used without any restriction for standard and roof brick guards.

IMPROVED APPLICABILITY

IMPROVED APPLICABILITY

Thanks to the lower weight of the Steel Deck LW, less weight has to be moved during assembly.

This increases both truck capacity and worker productivity. With an average assembly capacity of 3.3 man-hours per tonne of material, labor costs in this example can be reduced by up to 6 %, leading to long-term overall savings while considerably reducing the physical strain on the scaffolding erectors.

Benefits Designed For You

Benefits Designed For You

- Up to 10 % weight savings while retaining a high load-bearing capacity means lower labor costs, increased truck capacity, and improved ergonomics.

- A strong feeling of safety when walking on the deck thanks to transverse reinforcements in the surface.

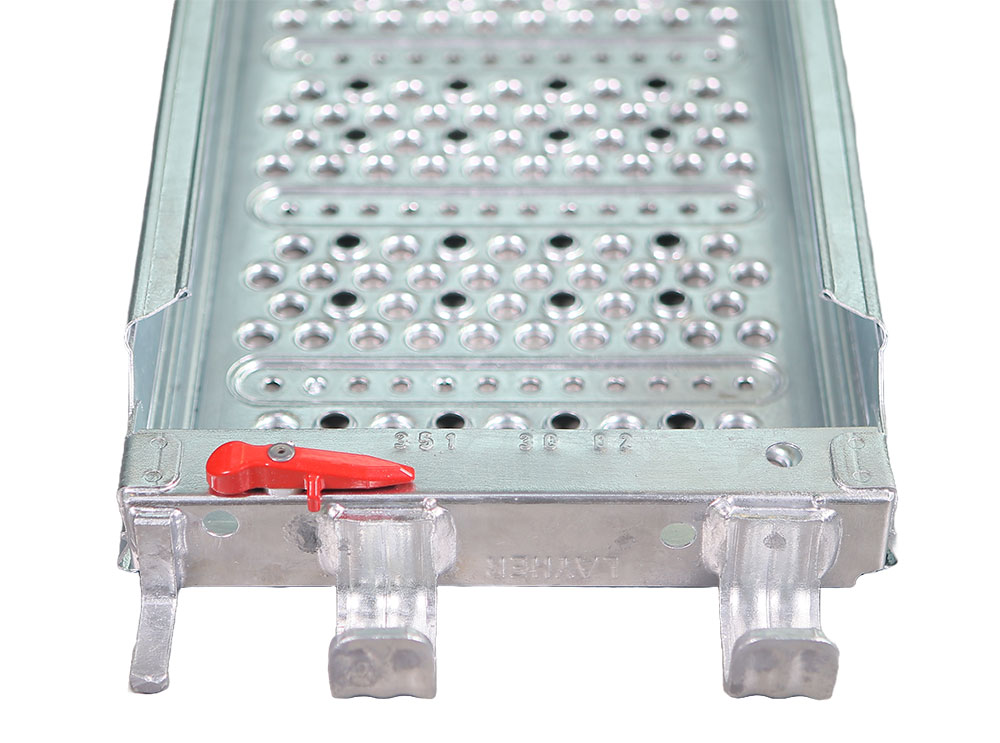

- Better grip thanks to optimized steel cap and the longitudinal profile, ensuring more ergonomic handling and greater safety

- Time-saving construction site erection and dismantling

- Cost savings through approximately 10% higher productivity

- It can be combined with steel decks of previous generations during assembly and transport.

EFFICIENCY DURING TRANSPORT AND ASSEMBLY

EFFICIENCY DURING TRANSPORT AND ASSEMBLY

Thanks to the lower weight of the Steel Deck LW, less weight has to be moved during assembly. This increases both truck capacity and worker productivity.

With an average assembly capacity of 3.3 man-hours per tonne of material, labor costs in this example can be reduced by 6 %., leading to long-term overall savings while considerably reducing the physical strain on the scaffolding erectors.

PROFITABILITY AND A SECURE FUTURE

PROFITABILITY AND A SECURE FUTURE

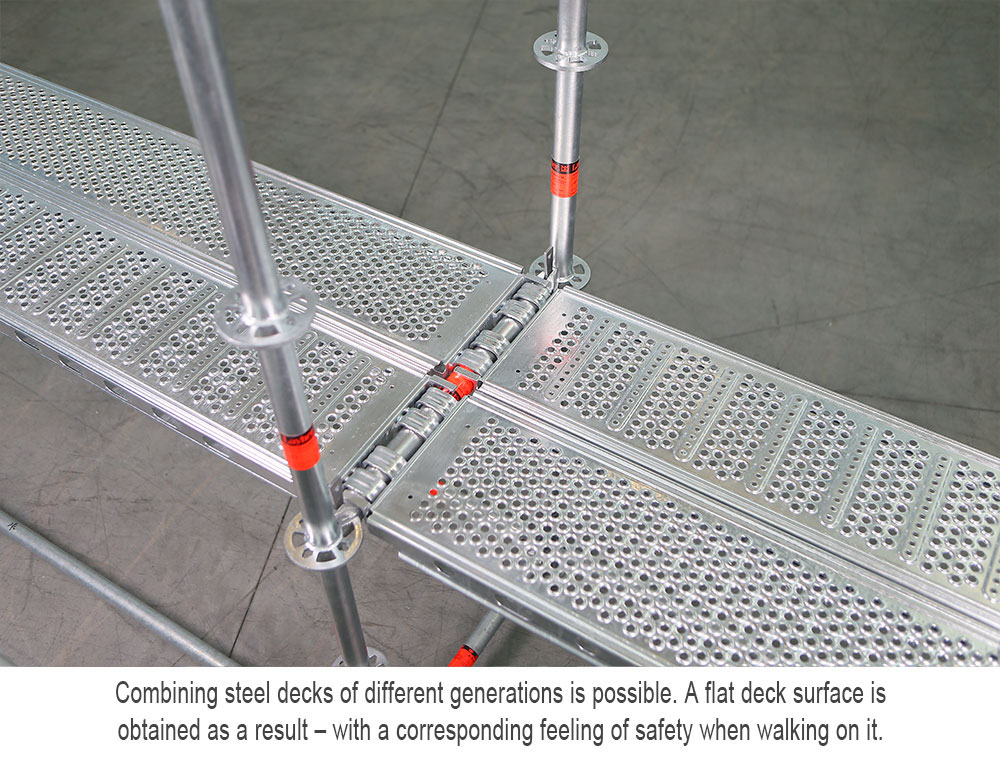

The Steel Deck LW ensures – as is usual at Layher – that investments are fully safeguarded since the deck can be installed together with all previous Layher scaffolding systems. The combination with steel decks of earlier generations presents no problems and results in a flat scaffolding deck surface. Stacking, too, is both easy and space-saving. As already familiar from earlier steel deck generations, the U-Steel Decks LW are also stacked in an interlocking manner. That minimizes the possible packing dimensions. It goes without saying that this stacking method is also possible in combination with steel decks of an earlier generation. All these measures result in high-value retention of your material stocks and their upgrading by purchasing innovative new products like the steel deck LW—a worthwhile investment.

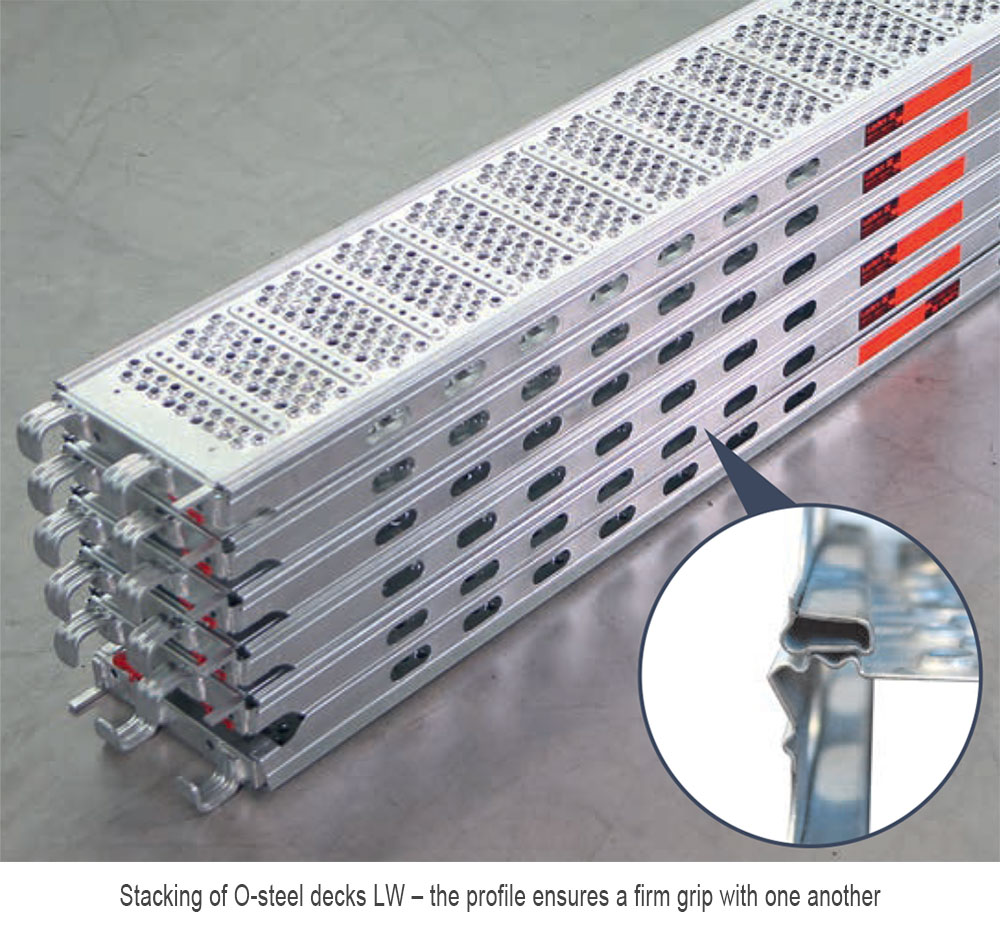

The O-Steel Decks LW are also familiar from earlier generations, stacked directly on top of one another. The longitudinal profile ensures here that the stacked decks cannot slip. The O-Steel Deck LW can also be combined with O-steel decks of earlier manufacture in a mixed stack.

The Steel Deck LW ensures – as is usual at Layher – that investments are fully safeguarded since the deck can be installed together with all previous Layher scaffolding systems. The combination with steel decks of earlier generations presents no problems and results in a flat scaffolding deck surface. Stacking, too, is both easy and space-saving. As already familiar from earlier steel deck generations, the U-Steel Decks LW are also stacked in an interlocking manner. That minimizes the possible packing dimensions. It goes without saying that this stacking method is also possible in combination with steel decks of an earlier generation. All these measures result in high-value retention of your material stocks and their upgrading by purchasing innovative new products like the steel deck LW—a worthwhile investment.

The O-Steel Decks LW are also familiar from earlier generations, stacked directly on top of one another. The longitudinal profile ensures here that the stacked decks cannot slip. The O-Steel Deck LW can also be combined with O-steel decks of earlier manufacture in a mixed stack.

LAYHER LIGHTWEIGHT – THE NEXT DIMENSION IN SCAFFOLDING

LAYHER LIGHTWEIGHT – THE NEXT DIMENSION IN SCAFFOLDING

Profitability and safety aren’t contradictions at Layher.

On the contrary, they’re what drive us: new materials, new production processes and design improvements to make our systems lighter, faster, stronger. And so even more economical.

Profitability and safety aren’t contradictions at Layher.

On the contrary, they’re what drive us: new materials, new production processes and design improvements to make our systems lighter, faster, stronger. And so even more economical.

THE LAYHER LIGHTWEIGHT PHILOSOPHY

THE LAYHER LIGHTWEIGHT PHILOSOPHY

OUR OVERRIDING PRIORITY IS OUR CUSTOMERS’ SUCCESS

To make scaffolding even more economical and even safer, Layher development engineers are constantly working on ingenious new developments. Our focus here is on the influencing factors for assembly performance, such as weight, shape and the number of components.

To achieve this, we constantly search for new materials and new production processes. Just a few additional components also continuously provide our customers with new fields of business, since the utilization of their material stocks is also a crucial economic factor. Thanks to uniform system dimensions and appropriate combination approvals, all our innovations are designed to be interchangeable with existing components of the Layher product portfolio – including our earlier product generations. This ensures investment security. The strengths of our integrated system.

OUR OVERRIDING PRIORITY IS OUR CUSTOMERS’ SUCCESS

To make scaffolding even more economical and even safer, Layher development engineers are constantly working on ingenious new developments. Our focus here is on the influencing factors for assembly performance, such as weight, shape and the number of components.

To achieve this, we constantly search for new materials and new production processes. Just a few additional components also continuously provide our customers with new fields of business, since the utilization of their material stocks is also a crucial economic factor. Thanks to uniform system dimensions and appropriate combination approvals, all our innovations are designed to be interchangeable with existing components of the Layher product portfolio – including our earlier product generations. This ensures investment security. The strengths of our integrated system.

LIGHTWEIGHT COMPONENTS CAN BE IDENTIFIED BY THE LUMINOUS RED LABEL WITH LAYHER BANDEROLE AND THE LAYHER LIGHTWEIGHT SEAL.

LIGHTWEIGHT COMPONENTS CAN BE IDENTIFIED BY THE LUMINOUS RED LABEL WITH LAYHER BANDEROLE AND THE LAYHER LIGHTWEIGHT SEAL.

LAYHER LIGHTWEIGT – MORE THAN JUST WEIGHT

LAYHER LIGHTWEIGT – MORE THAN JUST WEIGHT

Contact us for the Layher Lightweight brochure for more detailed product information and specifications including:

- The new auto lock function & redesigned wedge-head

- Increased headroom with Allround reinforced bridging ledgers LW

- Reduced shipping costs with Layher Lightweight components

- Allround Lightweight product specifications

- Weight comparisons: Allround Lightweight vs. Allround Standard

- SpeedyScaf Lightweight product specifications

NEW! LAYHER

STEEL DECK LIGHTWEIGHT

NEW! LAYHER STEEL DECK LIGHTWEIGHT

Layher’s Steel Deck Lightweight is 10% lighter yet maintains strength. This translates to faster assembly, improved ergonomics, and increased profitability.

LIVE ASSEMBLY OF LAYHER ALLROUND LIGHTWEIGHT

LIVE ASSEMBLY OF LAYHER ALLROUND LIGHTWEIGHT

Layher Lightweight is the result of a major, multi-year R&D project with a clearly defined objective: to make scaffolding easier, safer, and more cost effective.

LAYHER SPEEDYSCAF LIGHTWEIGHT

LAYHER SPEEDYSCAF LIGHTWEIGHT

A worthwhile investment. Faster assembly, lower transport weight, same load-bearing capacity. Less weight for more performance.

LAYHER ALLROUND LIGHTWEIGHT

LAYHER ALLROUND LIGHTWEIGHT

The lighter components increase the speed of assembly and also transport capacities – that saves real money.