BOILER MAINTENANCE WITH LAYHER SIM

Social rights activist and politician, Nelson Mandela, was probably the most famous person to have lived in the vast township of Soweto, Johannesburg. Mandela spent 27 years of his life in jail for anti-apartheid political offences before becoming South Africa’s first black president, an office that he held from 1994 to 1999, after the apartheid system was dismantle. The Duvha power plant is located just over 100 km west of Johannesburg. It has a total capacity of 3.6 GW and delivers power to the city and the entire region. Southey Contracting, which has operations throughout Africa and in the Middle East, was awarded the contract to perform maintenance on the plant’s boiler. The maintenance specialists created the interior work scaffolding with the Layher Allround System, using Layher SIM (Scaffolding Information Modelling) for digital project planning and support.

BOILER MAINTENANCE WITH LAYHER SIM

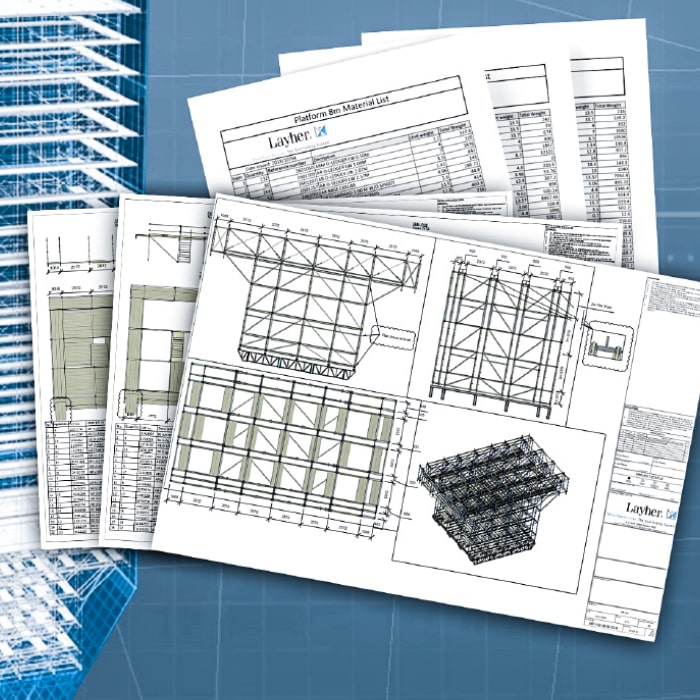

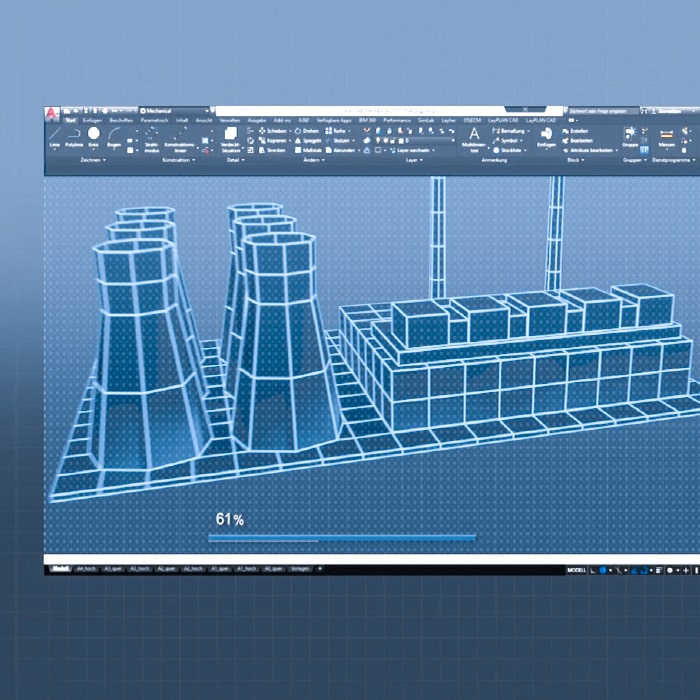

Digital planning ensures transparency in all stages of a scaffolding project, and it also helps to improve project safety and cost efficiency. By digitalising the process steps using Layher SIM, a process specifically developed for scaffolding projects, it was possible to improve budgeting and execution efficiency, and increase transparency for all the crews involved in the project.

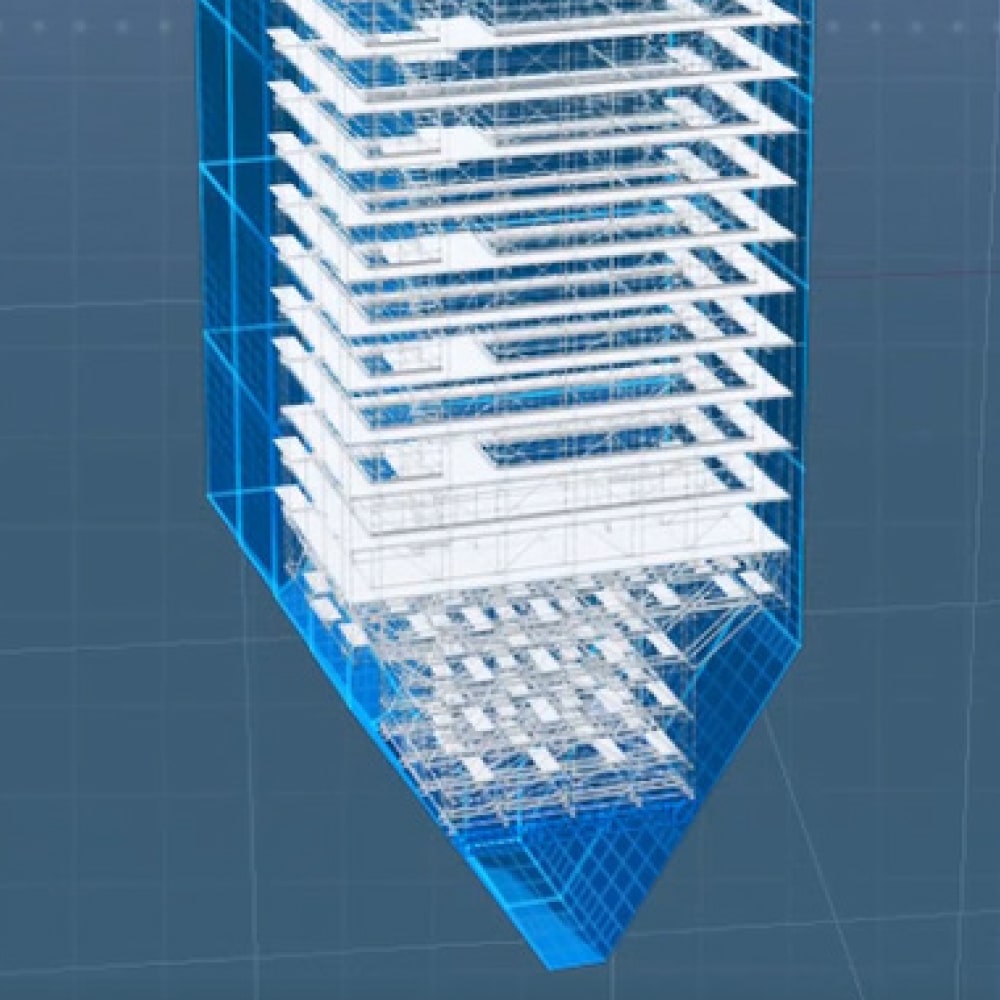

The lightweight generation of the Layher Allround System has many advantages for flexible and individual industrial scaffolding. In the boiler project it was used before the project kicked off to create informative 3D models of the planned scaffolding structure which were discussed in detail by the safety officers and reviewed for possible statics challenges.

3D models considerably simplify material logistics and the scaffolding build itself, and this advance planning process also minimises collisions with existing structures, which prevents time-consuming planning changes at the construction site.

“The 3D data from LayPLAN CAD are available to all crews during the entire SIM process for higher-level BIM (Building Information Modelling). They make it much easier for the crews at the construction site to collaborate with each other,” said Ettienne du Plessis, Project Manager at Layher South Africa.

“We saved three weeks of downtime.”

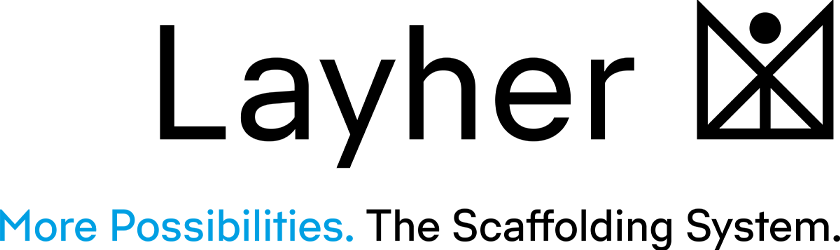

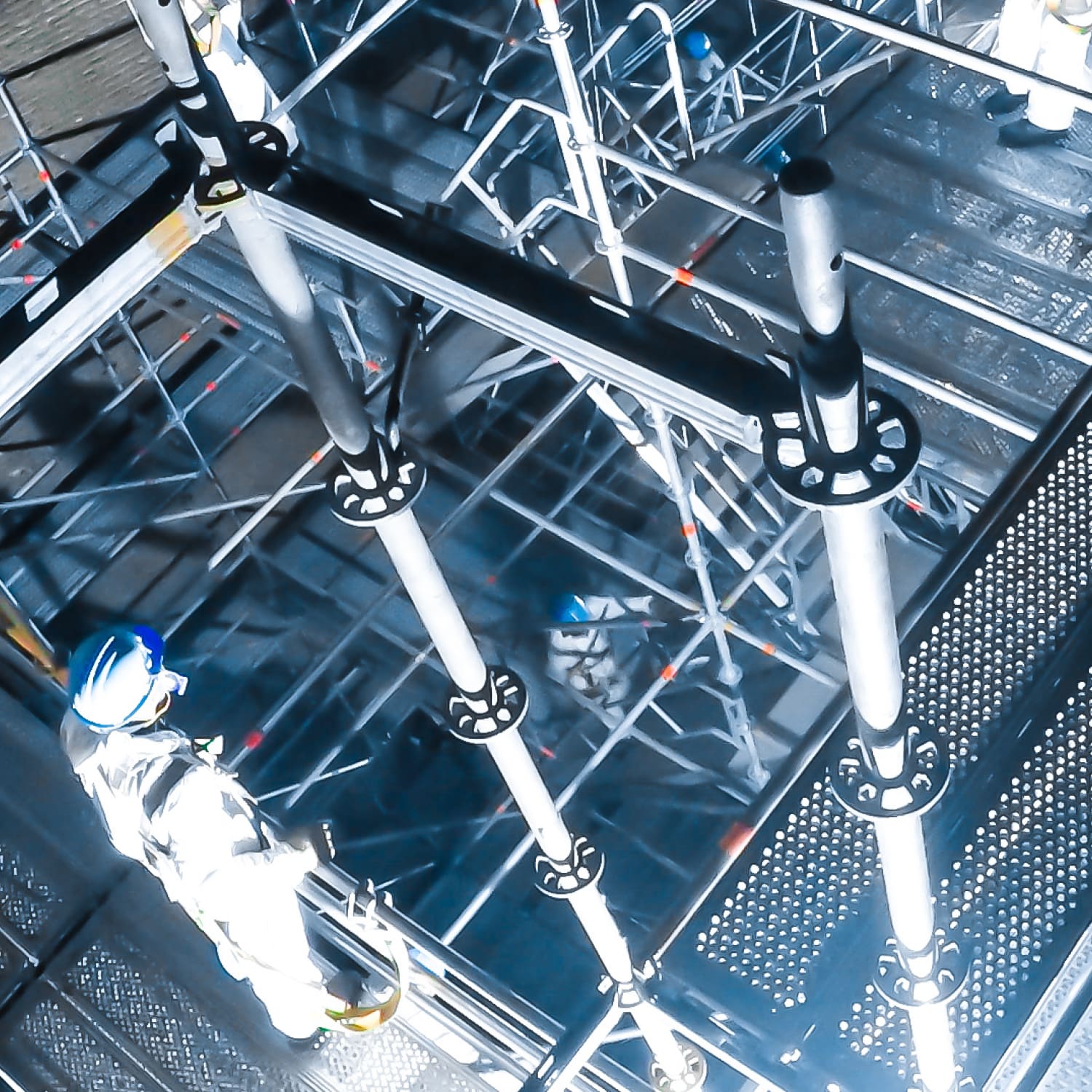

Southey Contracting was using the Layher Allround system for the first time, but the training and support provided to the scaffolding teams by Layher South Africa ensured that they were soon working efficiently and meeting all the deadlines. At 94 m high and 17 m wide, the boiler in Duvha is a massive structure. It took a total of 170 tonnes of Layher Allround material and an aluminum stairtower to make the inside walls of the boiler accessible.

The 40m-high scaffold with 22 levels was built in close collaboration with Layher South Africa. Detailed planning and the use of Allround Lightweight scaffold made it possible to reduce the weight of the structure by 50% and improve its load-bearing capacity.

The Allround FW System was also used for the lower tapered end of the boiler to provide a material-saving and high-load-bearing base for the scaffold that additionally made it possible to work on the walls at the same time. The teams were able to work efficiently, build up and dismantle the scaffold quickly and reduce the entire maintenance timeframe and thus plant downtime by 21 days, which resulted in substantial cost savings for the customer.

Digitalisation improves efficiency in scaffolding construction

The consistent treatment of scaffolding as an independent process in a construction project makes it easier to coordinate the individual steps and integrate them in a higher-level BIM process. This detailed advance planning with Layher SIM simplifies budgeting, logistics and the scaffolding build.

SIM helps to make the planning, assembly and management of temporary scaffolding structures more efficient. It is based on the modules of the integrated scaffolding planning software LayPLAN SUITE. Depending on requirements it can plan simple, pre-defined scaffolding applications and produce reliable 3D plans for complex scaffolding structures, including the realistic visualization of scaffoldings for construction process simulation and coordination.

LayPLAN CAD data can also be exported to the RSTAB statics program to create material lists and construction plans. “The Layher SIM consistently transfers the BIM principle to scaffolding. It is also helpful in non-civil-engineering projects and, more importantly, a practical addition to any project because it reduces costs, improves safety and increases commercial viability,” summarised Ettienne du Plessis, Project Manager at Layher South Africa.