HSBC CANADA’S SKYLINE REPLACEMENT PROJECT

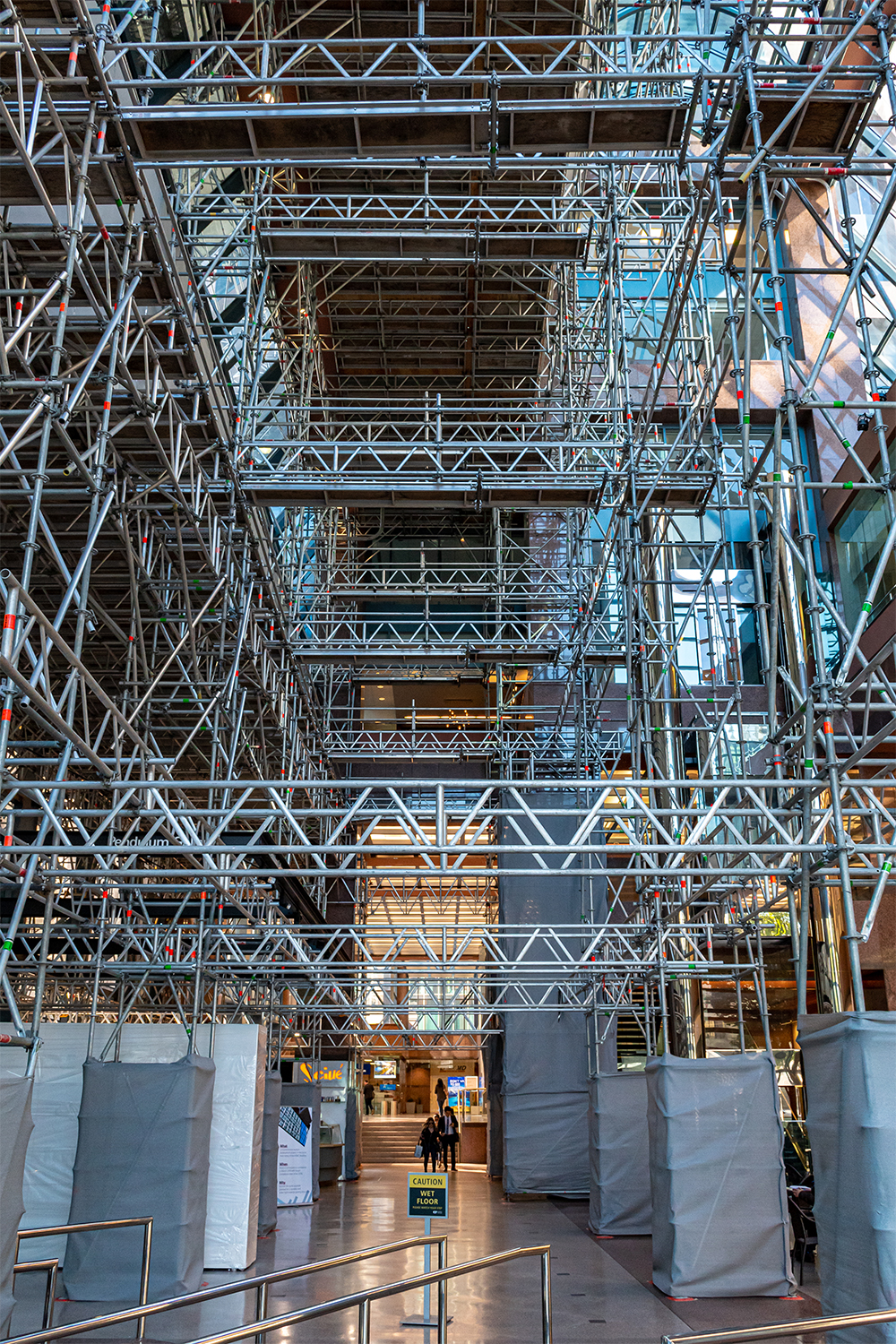

VANCOUVER, British Columbia – Project necessity proved to be the mother of scaffolding innovation in the recently completed Skylight Replacement Project for the HSBC Canada building in downtown Vancouver. The bustling 23-story office tower, home to HSBC Bank headquarters, boasts an expansive atrium lobby that posed a unique set of challenges during replacement.

For starters, the floor-to-ceiling tempered glass lobby measures approximately four stories and houses a variety of businesses – including a café and art gallery – and comes complete with a working 27-meter pendulum as its crown jewel.

When awarded the project, contractor Skyline Scaffold knew that a custom configuration was critical to getting the job done efficiently while accommodating operating businesses, customers, and the building’s unique art piece. “We typically take on a fair bit of gantry and hoist work, but this site made for a challenging combination, said Arka Chorbajian of Skyline Scaffold.

For the project, Skyline turned to Layher scaffolding and component parts, relying on traditional scaffolding pieces – like the Layher Allround® and 450/750 Lattice Beams – in addition to the Layher Keder XL Roof System and Layher Protect Panels to design the scaffolding arrangement.

“We put a premium on products that allow us to maintain an edge over our competitors,” said Chorbajian. “Layher is the only firm we trust to keep pushing the quality and innovative products we need to keep our clients safe and service their unique site requirements.”

VANCOUVER, British Columbia – Project necessity proved to be the mother of scaffolding innovation in the recently completed Skylight Replacement Project for the HSBC Canada building in downtown Vancouver. The bustling 23-story office tower, home to HSBC Bank headquarters, boasts an expansive atrium lobby that posed a unique set of challenges during replacement.

For starters, the floor-to-ceiling tempered glass lobby measures approximately four stories and houses a variety of businesses – including a café and art gallery – and comes complete with a working 27-meter pendulum as its crown jewel.

When awarded the project, contractor Skyline Scaffold knew that a custom configuration was critical to getting the job done efficiently while accommodating operating businesses, customers, and the building’s unique art piece. “We typically take on a fair bit of gantry and hoist work, but this site made for a challenging combination, said Arka Chorbajian of Skyline Scaffold.

For the project, Skyline turned to Layher scaffolding and component parts, relying on traditional scaffolding pieces – like the Layher Allround® and 450/750 Lattice Beams – in addition to the Layher Keder XL Roof System and Layher Protect Panels to design the scaffolding arrangement.

“We put a premium on products that allow us to maintain an edge over our competitors,” said Chorbajian. “Layher is the only firm we trust to keep pushing the quality and innovative products we need to keep our clients safe and service their unique site requirements.”

To keep outdoor sidewalks secure and accessible, Skyline outfitted Layher Allround scaffolding structure with interlocking Protect Panels that kept walking paths clear of debris and work out of sight. The panels produce a tight seal that kept commuters protected from wind, rain, and construction noise.

“We consult heavily with clients during bid to understand their goals, then suggest systems and innovative solutions,” said Chorbajian. “Our employees and customers deserve the peace of mind of knowing they will be working on the safest equipment money can buy, with the widest number of applications available.”

Inside, traditional Layher Allround provided the base structure necessary to reach the roof to begin the work of skylight replacement. Skyline used Layher lightweight lattice beams to support the heaviest loads at the widest spans. High-tensile steel reduced the weight of the structure by 10 to 12 percent, resulting in a reduction in labor and freight cost for the company. Interlocking rosettes further contributed to timely work, ensuring tool-free assembly and a secure connection system.

At the top, Skyline constructed an asymmetrical, pitched Layher Keder XL Roof to protect the building while its glass panels were removed. “We used Layher tripod runway systems for the Keder roof in addition to the diagonal travelers, which have articulated hoisting systems of their own,” said Chorbajian. The Layher Keder XL System is weatherproof and lightweight, which makes it ideal for spanning small and medium-sized gaps without the need for a crane.

To swiftly transfer and replace each panel, Skyline created a hoist and trolley system that moved freely along a scaffolding beam. Each panel was lowered to the street below and replaced with a new glass panel. Due to the busy city streets, staging a crane or even mobile crane anywhere near the site was impossible. “We built a 2000-pound gantry, above street, so flatbeds could be loaded and unloaded directly from a single lane below,” said Chorbajian.

In the end, the scaffolding build was completed with an 8-person crew resulting in limited disturbance to businesses and customers.

“Not only does Layher have the best sales and technical support in the industry, but its overall catalog of cutting-edge components are unmatched,” said Chorbajian.“Layher truly understands the ‘safety, quality, quantity’ mantra, and we can rely on them to assist us in building our business around these mutually shared principles.”