ZOO-BASED BIOGAS PLANT WITH LAYHER MATERIALS

KERECT SCAFFOLD LTD REALIZES CANADA’S FIRST ZOO-BASED BIOGAS PLANT WITH LAYHER MATERIALS

Toronto – Kerect Scaffold Ltd recently supported the creation of Canada’s first zoo-based biogas plant by cooperative developer Zooshare. Located on Meadowvale Road across from the Toronto zoo, the project will convert animal manure and local food waste into renewable power for the Ontario grid. The plant is expected to reduce carbon dioxide emissions by 10,000 tonnes per year and generate 4.1 million kilowatt-hours in energy once fully operational, according to the Zooshare website.

Kris Koach, owner of Kerect Scaffold, responded to an initial call for bids in December 2019. Zooshare sought scaffolding contractors to facilitate concrete pours for the first of three facility tanks critical to the anaerobic process that converts waste to energy.

This plant’s energy conversion occurs via a thermochemical process when biomass is heated in an oxygen-starved environment, as described by Environment Canada. Because it’s critical to monitor oxygen and temperature, storage plays an important role and requires meticulous planning.

Initially, the bid sought scaffolding contractors solely in support of the outside wall, with shoring support planned for the inside. But once Koach became acquainted with the project, he recognized an opportunity for his company to offer additional value.

“I knew if I provided an effective way of scaffolding, it would be cheaper,” said Koach, an industry veteran, “If you focus on engineering, that’s the easiest solution.”

KERECT SCAFFOLD LTD REALIZES CANADA’S FIRST ZOO-BASED BIOGAS PLANT WITH LAYHER MATERIALS

Toronto – Kerect Scaffold Ltd recently supported the creation of Canada’s first zoo-based biogas plant by cooperative developer Zooshare. Located on Meadowvale Road across from the Toronto zoo, the project will convert animal manure and local food waste into renewable power for the Ontario grid. The plant is expected to reduce carbon dioxide emissions by 10,000 tonnes per year and generate 4.1 million kilowatt-hours in energy once fully operational, according to the Zooshare website.

Kris Koach, owner of Kerect Scaffold, responded to an initial call for bids in December 2019. Zooshare sought scaffolding contractors to facilitate concrete pours for the first of three facility tanks critical to the anaerobic process that converts waste to energy.

This plant’s energy conversion occurs via a thermochemical process when biomass is heated in an oxygen-starved environment, as described by Environment Canada. Because it’s critical to monitor oxygen and temperature, storage plays an important role and requires meticulous planning.

Initially, the bid sought scaffolding contractors solely in support of the outside wall, with shoring support planned for the inside. But once Koach became acquainted with the project, he recognized an opportunity for his company to offer additional value.

“I knew if I provided an effective way of scaffolding, it would be cheaper,” said Koach, an industry veteran, “If you focus on engineering, that’s the easiest solution.”

He offered to bid using scaffolding both in support of the outside wall and as shoring to support the inside and heavy roof. Zooshare agreed to review the bid, and Koach got to work on a potential design.

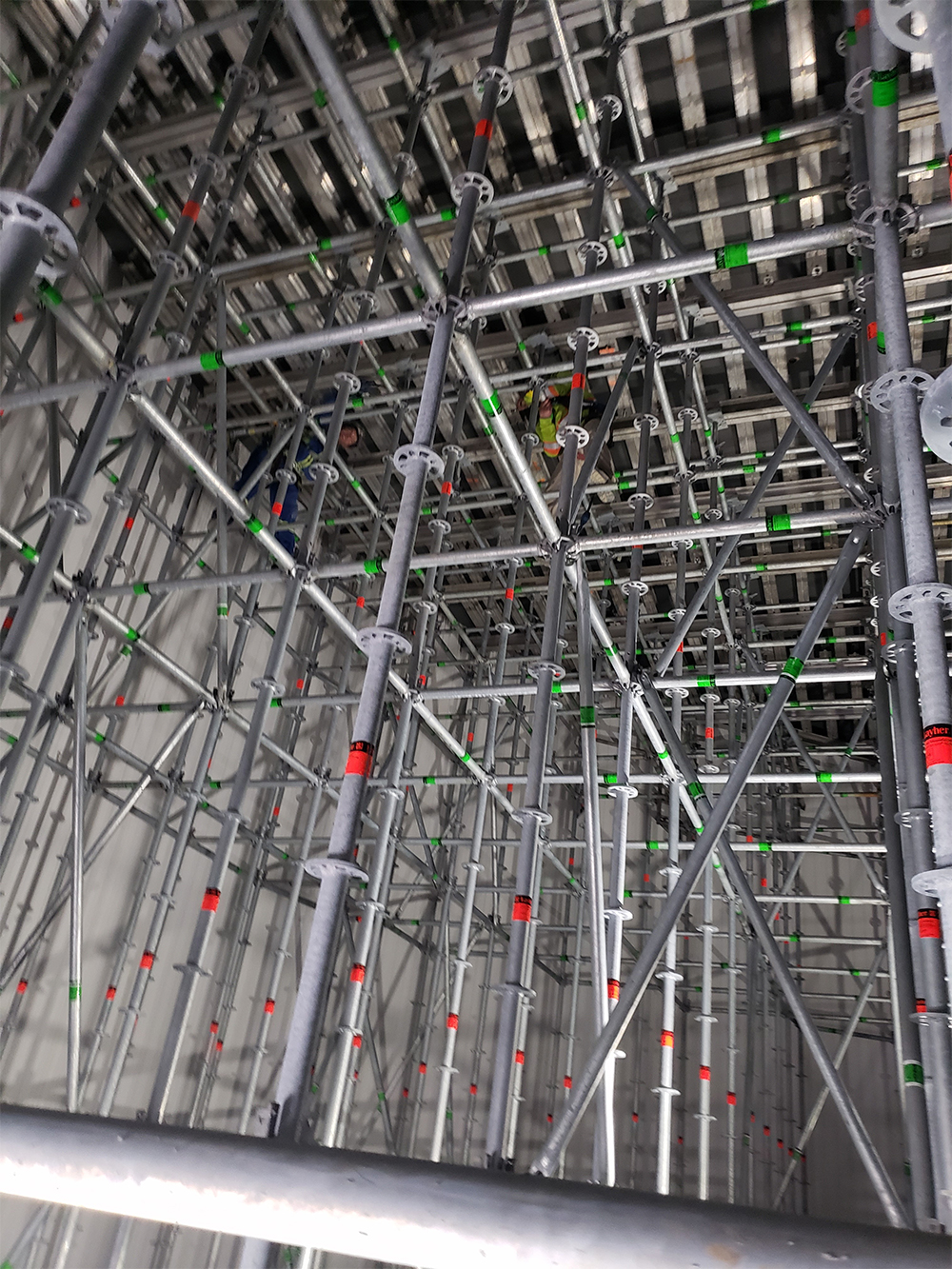

Zooshare specifications for the first tank called for a construction measuring 10 metres in height and 15 metres wall to wall with a 46-centimeter-thick concrete roof. Koach’s design included a 1 metre by 2 metre grid made up of approximately 187 vertical legs of Layher Allround® scaffolding to support the outer wall. A brace every 2 metres provided additional stability, with 65 cm by 65 cm ledgers around the corners. Layher Allround – used as shoring – made up the interior, with Octaform throughout.

“It uses more [scaffolding] legs, but it’s cheaper,” said Koach of the plan, noting that Layher scaffold can accomplish similar load-bearing to shoring with smart design. The cost of shoring rental is typically higher than scaffolding due to its ability to withstand concrete loads without the need for additional engineering work.

Layher Allround scaffolding can support heavy loads and includes variable spacing for standards to accommodate designs matched for the intended weight. Heavy duty towers made of bundled Allround standards are capable of carrying loads of up to 50 tonnes.

Seeing the benefit inherit in the bid, Zooshare awarded Kerect Scaffold the bid in January with work slated to begin in just a few weeks. Knowing the extent of components involved, and that removing them from the company stock would likely drain the yard, Koach asked Layher representative Ryan Freedman to ship directly from the Layher supply.

“Because of the specific size of the ledgers that were needed, I had to rent quite a bit,” said Koach, “Mr. Freedman and his crew are fantastic. It took only a few days to get to the project site [in Toronto] from branches in Baltimore, [Maryland] and [Ocala], Florida.”

Layher data estimates reduced component weights combined with logical, coordinated shipping practices can prevent the need for 1 of every 10 shipping loads, transferring savings to clients.

“Both teams coordinated each load to maximize the materials on each truck and efficiency for offloading,” said Freedman, “Overall, this created a safer and more productive workplace for all involved.”

Once materials were delivered, Kerect Scaffold accomplished the job with eight crew members in three weeks’ time, working fifteen shifts.

With January temperatures reaching negative thirty, weather presented a familiar challenge for Toronto inhabitants. Koach explained that the lighter weights of Layher scaffolding made a significant difference for crew members working eight-hour shifts in harsh weather and helped them come in under budget.

“A little bit less weight makes a big difference,” says Koach, who exclusively uses Layher scaffolding. Layher high-tensile steel products come in over 4,000 parts with corrosion protected galvanized steel to make up the Layher Allround system. Users report a 10 percent faster build with Layher lightweight products, reducing field hours and exposure to risk. Contractors find it particularly appealing for its ability to withstand extreme weather.

Pleased with their work on the first tank, Zooshare hired Kerect to continue work on the second in July. For the second tank, an open STEP measuring 32 metres across, Koach’s design called for a 3 metre by 3 metre scaffold along the perimeter utilizing Layher Allround.

Altogether, Koach’s tank designs called for over 45 tonnes of Layher materials delivered in a quick turnaround to ensure project success. Representative Freedman reflected, “We had some tight deadlines to meet, and with the strong partnership we have built with Kerect over of the years, we really wanted to exceed expectations.”

As owner of Kerect Scaffold, Koach attributed his affinity for Layher scaffolding to an investment in future planning. “Other companies have a mishmash of material […] they don’t like to think long term,” said Koach, “With Layher, you get more for your dollar and it looks clean.”

As of October 2020, Zooshare has not sought bids on a third tank, but when they do Kerect Scaffold Ltd and Layher will be ready to team up again and get to work.