LAYHER IMPROVES SAFETY AND PRODUCTIVITY

IN SHIPBUILDING & OFFSHORE

Meeting scheduled deadlines while remaining within the budget parameters are two primary focuses of any shipbuilding and offshore activity. From new construction to maintenance, repairing, servicing, and upgrading, staying on schedule and within a set budget is critical. This is Layher’s strength. With more than 75 years of experience, Layher’s Allround® modular scaffolding is the standard for the shipbuilding and offshore industry. It allows companies to maintain their fleets and grow their businesses successfully. We are the scaffolding standard for the shipbuilding and offshore industry.

SIMPLE, VERSATILE, EASY-TO-HANDLE, SAFER, ADAPTABLE, AND TRANSPORTABLE

SIMPLE, VERSATILE, EASY-TO-HANDLE, SAFER, ADAPTABLE, AND TRANSPORTABLE

These are just some of the adjectives our loyal clients in the Shipbuilding and Offshore Industry have used to describe our scaffolding. They depict our world-class products and also indicate why our clients keep coming back. They continue to deploy scaffolding from Layher as we continue to improve an already world-class product.

SCAFFOLD SYSTEM SOLUTIONS

SAFER AND FLAT WORK PLATFORMS – OPTIMISED FOR THE JOB TO BE DONE

Since no plant is like another, scaffolding systems have to be flexible and adaptable. With Layher scaffolding, that’s no problem: Thanks to the option of laying the decks over the rosettes, a gap-free solution can be accomplished without additional expense or effort. For special cases specific to the site, we offer a comprehensive portfolio of expansion parts for achieving completely closed work surfaces within the system.

Solution-oriented components

- Special decks

- Penetrations with interchangeable ledgers

- Telescoping scaffolding decks

- Gap deck

- Steel gap cover

- Steel plank

ACCESS

Well-designed and correctly arranged accesses improve efficiency and also productivity at the site.

Solution-oriented components

- Internal ladder access

- Platform stairs

- Stairtowers 200

ROOFS & WALL SYSTEMS

The extensive Layher range of protective systems extends from compact weather protection roofs to wide-span roof solutions and enclosure systems which can be kept at a lower pressure.

Solution-oriented components

- Roof Systems

- Wall systems

SHORING

Shoring structures are an important factor in ensuring more safety and efficiency for in-site concreting work, particularly when building a new plant.

Solution-oriented components

- New plant construction with Allround Scaffolding

VESSELS

Closing the gaps in round equipment is often a challenge. Covering with steel or wood planks can be classified as a risk of tripping. In addition, these must be protected against unintentional lifting and slipping, which can cause problems depending on the type of soil used.

Solution-oriented components

- Flexible angle selection of Allround rosette

- Work surface adaptation for circular scaffolding

SUSPENDED SCAFFOLDING SOLUTIONS

When the work areas are very high up, standard scaffolding structures can often be uneconomical due to high material and labour costs. With Allround Scaffolding, suspended solutions can be achieved without any problem in such cases. Pull-resistant securing of the standards with hinged pins or by bolting them together allows forces to be optimally transmitted.

Solution-oriented components

- Suspended scaffolding structures

- Suspended scaffolding accessories

- Cantilevering and crane movability

Layher Suspended Scaffolding Solutions

CRANE MOVABILITY

The high fitting precision in the Layher system enables scaffolding structures to be preassembled on the ground, complete or in individual segments. Thanks to pull-resistant connection of all individual parts, they can be moved quickly and easily into position using a crane. This is a major advantage when it comes to efficiency and profitability. At the same time, safety during assembly increases many times over. Because the best fall protection is when there is no risk of falls in the first place.

Solution-oriented components

- Stairtowers

- Work Scaffolding

- Bridging

BRIDGING

Small spans are possible with Allround Scaffolding without the use of additional components, using standards, ledgers, and diagonal braces as a lattice structure.

Solution-oriented components

- Allround Scaffolding standard parts

- Lattice beams

- Aluminum FlexBeam

- Allround Bridging System

FIRE SAFETY, WOOD-FREE SOLUTIONS

Reduction of the fire risk is a requirement frequently expressed for scaffolding in refineries, chemical factories, and other fire-sensitive industrial plants. Components made of wood can be ruled out for obvious reasons. Layher has the optimum alternatives: system decks and matching toe boards made of steel or aluminum. Gap solutions made of steel, and scaffolding coverings made of low-inflammability tarpaulins or the Protect System, round off the range.

Solution-oriented components

- Steel deck LW

- Toeboards of steel and aluminum

- Steel plank

SCAFFOLD SYSTEM SOLUTIONS

SAFER AND FLAT WORK PLATFORMS – OPTIMISED FOR THE JOB TO BE DONE

Since no plant is like another, scaffolding systems have to be flexible and adaptable. With Layher scaffolding, that’s no problem: Thanks to the option of laying the decks over the rosettes, a gap-free solution can be accomplished without additional expense or effort. For special cases specific to the site, we offer a comprehensive portfolio of expansion parts for achieving completely closed work surfaces within the system.

Solution-oriented components

- Special decks

- Penetrations with interchangeable ledgers

- Telescoping scaffolding decks

- Gap deck

- Steel gap cover

- Steel plank

VESSELS

Closing the gaps in round equipment is often a challenge. Covering with steel or wood planks can be classified as a risk of tripping. In addition, these must be protected against unintentional lifting and slipping, which can cause problems depending on the type of soil used.

Solution-oriented components

- Flexible angle selection of Allround rosette

- Work surface adaptation for circular scaffolding

Layher Suspended Scaffolding Solutions

SUSPENDED SCAFFOLDING SOLUTIONS

When the work areas are very high up, standard scaffolding structures can often be uneconomical due to high material and labour costs. With Allround Scaffolding, suspended solutions can be achieved without any problem in such cases. Pull-resistant securing of the standards with hinged pins or by bolting them together allows forces to be optimally transmitted.

Solution-oriented components

- Suspended scaffolding structures

- Suspended scaffolding accessories

- Cantilevering and crane movability

CRANE MOVABILITY

The high fitting precision in the Layher system enables scaffolding structures to be preassembled on the ground, complete or in individual segments. Thanks to pull-resistant connection of all individual parts, they can be moved quickly and easily into position using a crane. This is a major advantage when it comes to efficiency and profitability. At the same time, safety during assembly increases many times over. Because the best fall protection is when there is no risk of falls in the first place.

Solution-oriented components

- Stairtowers

- Work Scaffolding

- Bridging

FIRE SAFETY, WOOD-FREE SOLUTIONS

Reduction of the fire risk is a requirement frequently expressed for scaffolding in refineries, chemical factories, and other fire-sensitive industrial plants. Components made of wood can be ruled out for obvious reasons. Layher has the optimum alternatives: system decks and matching toe boards made of steel or aluminum. Gap solutions made of steel, and scaffolding coverings made of low-inflammability tarpaulins or the Protect System, round off the range.

Solution-oriented components

- Steel deck LW

- Toeboards of steel and aluminum

- Steel plank

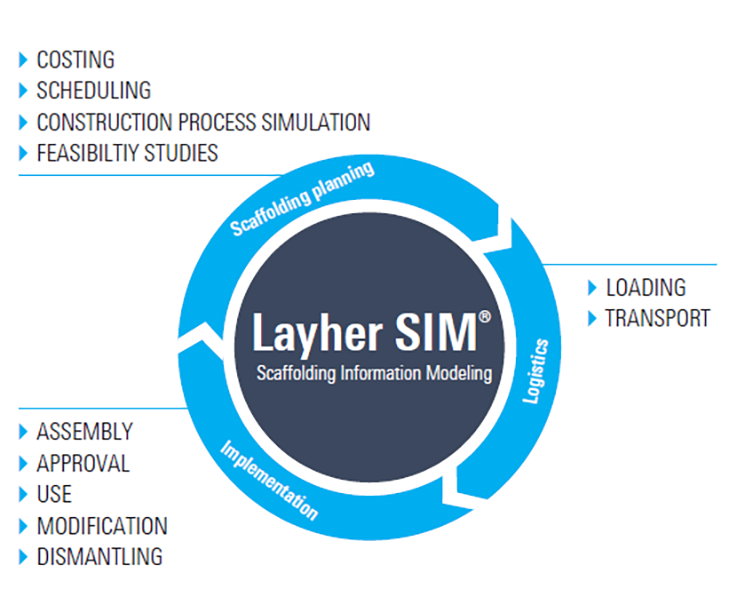

THE FUTURE OF SCAFFOLDING IN THE SHIPBUILDING AND OFFSHORE INDUSTRY IS DIGITAL — AND ITS NAME IS SIM

SIM or Scaffolding Information Modeling is a scaffolding design process based on 3D models. At Layher, we use it to meet the precise requirements of industrial scaffolding, including those used in the cement industry. SIM helps us to plan, assemble, and strategically manage temporary scaffolding structures in the most efficient ways possible.

SIM allows you to:

- Plan your scaffolding in detail before it is being built

- Strategize and schedule your project with certainty and confidence

- Increase the safety and profitability of your project

- Provide transparency and cost control for its lifespan

- Budget, schedule, simulate the construction processes and conduct feasibility studies

- Assist in implementation, including assembly, approval, use, modification, and dismantling of any scaffolding project within a shipbuilding and offshore industry

- Verify structural loads

LAYPLAN SUITE – THE INTEGRATED SOFTWARE SOLUTION.

Time and material are crucial factors in scaffolding construction.

To make the most efficient use of both, the Layher range includes the practical scaffolding planning software LayPLAN.

Increased Profits, Improved Safety, Developed Efficiency

LAYHER ALLROUND SCAFFOLDING

Essential for Shipbuilding and Offshore Scaffolding

Our Allround scaffolding is the most comprehensive scaffolding system for shipyards and offshore applications in the world. Its unmatched adaptability and flexibility make it the scaffolding of choice for shipbuilding and offshore companies globally. Whether it is required on a ship’s curved hulls, propeller, rudder, on the superstructures, or inside the cargo area, Layher has the solution for your requirements.

Layher Allround scaffolding is an investment in a comprehensive system that has been perfected and proven its worth time and time again. With a long list of accessories, Layher has become the favored partner for quick access for repairs and servicing.

Layher Cassette & Keder XL Roof

Weather delays are a thing of the past in the shipbuilding and offshore industry thanks to our Cassette and Keder XL Roof.

Our Cassette Roof is a versatile and modular product that provides strong temporary weather protection. It can be assembled on almost all scaffolding systems and allows spans of up to 27.1m-89ft.. Layher’s Cassette Roof will allow you to continue your work aboard the ship regardless of the weather. Thereby allowing you to adhere to your schedule with maximum efficiency.

Layher’s Keder XL Roof is the perfect lightweight and economical way to ensure proper weather protection. This attractive covering is relatively inexpensive, spanning a distance of up to 30m-98ft.

Layher Protect System

For work such as sandblasting or asbestos removal on a ship, Layher’s Protect System is ideal. Layher’s Protect Systems let you build a solid wall around your scaffold structure. It reduces and, in many cases, eliminates the need for shrink-wrap and its constant maintenance. The Protect System comes in a variety of components, including solid wall panels, corner cassettes, translucent panels, and doors and is fully reusable and long lasting.

The Layher Difference

No matter what your shipbuilding and/or offshore project requires, you can choose confidently from Layher’s wide-range of parts and accessories. They are made of the highest quality selected from materials and manufactured with precision using steady quality controls. Our products are known for their stability, meaning they have a tremendously high-load bearing capacity designed to be used frequently. Alternatively, they can be used as a sub-structure as well.

LAYHER TRAINING & ON-SITE SUPPORT

On-site, In-house, and Remote Training Options

Our industry and product-specific training courses can be provided either on-site, in-house, or remotely via our qualified trainers. The training will address the dual objectives of safety and continuous improvement within the demanding shipbuilding and offshore industry. Our practice is structured to match all levels of expertise. The courses cover a variety of topics from correct scaffolding installation to highlighting the benefits that can arise from the use of authentic Layher equipment.

We offer a variety of classes, both theoretical and hands-on in approach. The training will be tailored to the specific needs of the project. Each course has a duration of one to several days. For personalized attention, the classes are small, with no more than nine trainees per class.

Layher On-Site support provides an extra resource for your most critical projects. Our experts will be there to answer your questions and ensure that your shipbuilding and offshore project is progressing as planned. Layher engineers often work together with field supervisors to ensure effective logistics planning, including transportation and loading. They provide straight-forward communication between trades and a reduction in change orders.

LAYHER-THE WORLD-LEADER IN SCAFFOLDING

You could say we’ve been doing the same old thing for the last 75 years: revolutionizing the scaffolding industry with our simple yet revolutionary design. You might wonder why we keep doing it? The answer is simple. It’s for the client. It’s always been for the client. We want our clients to succeed. Our products are the result of superior engineering, a quality product, and the combined experience of our team. Together we produce world-class scaffolding and continue to work towards improving that product on a daily basis.

LAYHER, YOUR PARTNER IN SUCCESS

Questions regarding how Layher can help your project, please do not hesitate to contact us.