5 SCAFFOLDING CONSIDERATIONS THAT

SAVE PLANT MANAGERS MILLIONS

LAYHER INC.

Article first posted on BIC Magazine

WHILE MANY PLANTS SPEND A SIGNIFICANT PORTION OF THEIR OPERATING BUDGETS ON SCAFFOLDING, EVEN THE MOST ASTUTE MANAGER MAY OVERLOOK IT AS AN ITEM WORTH SCRUTINY.

Afterall, if you’re bringing in millions in revenue every operational hour, why would a line-item worth hundreds of thousands be worth a closer look?

The simple answer is one procurement often misses: Differences in scaffolding can account for hundreds of operational hours saved over the course of plant Maintenance, Startup, and Shutdown, making it an item best left for management.

Indeed, the scaffolding a manager chooses to maintain onsite, or chooses via a contractor, reverberates over the course of a plant’s life because scaffolding is more than a means of everyday maintenance, but a critical tool that affects downtime. What’s more, superior scaffolding reduces risk that otherwise opens a plant up to liability.

In terms of innovation, versatility, partnership, planning support, and the consistency that comes with a proven track-record, superior scaffolding saves plants money by increasing the speed of assembly while reducing risk.

Here are five questions to consider to save you money when making scaffolding decisions for your plant.

IS MY SCAFFOLDING (OR SCAFFOLDING CONTRACTOR) KEEPING UP WITH THE LATEST SCAFFOLDING INNOVATIONS?

If you’re unfamiliar with the minutiae of the scaffolding world, it may seem like not much has changed in the past 50 years, but that couldn’t be further from the truth. Dedicated scaffolders, like Layher scaffolding, have made their mark on the industry, innovating with lighter weights and safety considerations that increase productivity in significant ways.

First, lighter weights decrease worker fatigue over time – a vital consideration when you’re maintaining crews over the course of 24-72 hours straight. Halfway through a 12-hour shift, this time savings becomes apparent, frequently shaving off several hours by work’s end when compared to weightier alternatives.

This consideration of lighter weights is lost on procurement departments that ask scaffolders to quote scaffolding in price per ton. With lighter weights, you get more components per ton, making the comparison ineffective for decision making – yet another reason to leave this one to the managers.

Then there are innovations when it comes to the components themselves. These innovations include products with a multiplicity of uses, like the Layher Allround – the choice of many Oil & Gas refineries – that meet a plant’s need for unbeatable flexibility, accessibility, and adaptability. Layher maintains over 4,000 different parts in stock with supply yards all over North America.

But perhaps the most significant innovations are regarding safety. Safety-inspired innovations include built-in safety features that minimize risks that otherwise open your plant up to additional cost. These include everything from materials-testing during manufacturing to bolt-free assembly, and advanced guardrails to metal decking and metal toe boards to reduce burn rate.

Layher engineers its products for ease of assembly and disassembly, maximizing strength while minimizing weight to deliver optimum performance with safety at the forefront.

DOES MY SCAFFOLDING (OR MY CONTRACTOR’S SCAFFOLDING) ADAPT SEAMLESSLY TO SITE CONDITIONS?

For complex scaffolding projects, versatility is synonymous with speed, providing scaffolders with the means to adapt to site conditions with ease while reducing the need for change orders.

This is of particular importance in plants where scaffolding is often complicated by jutting pipes, valves, and other equipment that must be accommodated. It’s one thing to build a simple 5ft x 5ft x 10 ft scaffold and another to build through and around complicated structures.

For this reason, versatility is key. Adaptability provides immediate scaffolding solutions via multiple component options. In contrast, scaffolding with few component options may necessitate costly custom builds, creeping up the project timeline and adding downtime hours.

In short, scaffold buyer beware. Real world conditions differ from the parking lots of scaffold demonstrations. Plant managers take their plants farther, faster when they choose scaffolding that can be relied upon for versatility in addition to quality.

HOW AM I INCENTIVIZING (OR DISINCENTIVIZING) MY SCAFFOLDING CONTRACTOR TO PUT MY PLANT’S NEEDS FIRST?

First things first: take the decision of which scaffolding contractor and materials to choose out of the hands of purchasing, or at least educate them regarding your needs.

Purchasers are often rewarded for shaving as much off the purchase price as possible, but this savings is negligible when compared to losing operating hours. Unfortunately, this negative reinforcement trickles down to contractors.

Because scaffolders are used to responding to requests for price per ton, they are often disincentivized from pursuing lighter weight innovations that save you time and money. Placing scaffolding decisions in the hands of management is a simple first step in ensuring you choose a contractor that keeps your operation top of mind.

Once you’ve made the switch, bring scaffolders into the conversation. Scaffolding contractors that reduce downtime are easily rewarded with loyalty, but you need to give them the opportunity to demonstrate that time and money has been saved.

Engaging scaffolders as full team members recasts your relationship as a partnership that incentivizes fuller participation. Layher prides itself on its ability to improve customer operations and cultivates a culture of partnership that encourages proactive engagement that benefits you.

When you show scaffolding contractors you understand they have the ability to affect change on your Maintenance, Startup, Shutdown project, they’ll be more inclined to keep your best interests in mind. Reward them with longer contracts that reflect your appreciation and increase their job security.

IN WHAT WAYS DOES MY SCAFFOLDER OFFER PLANNING SUPPORT?

The most challenging part of any scaffolding project usually involves planning and logistics. Be sure to choose a scaffolder that is involved in ensuring a productive build through support in these crucial initial project phases.

Support includes scaffolding-related cost preparation, scheduling, design, build modeling, and feasibility studies during the planning phase, and loading and transport during logistics. Consistent, organized effort during these phases facilitating faster builds and minimizes safety risks.

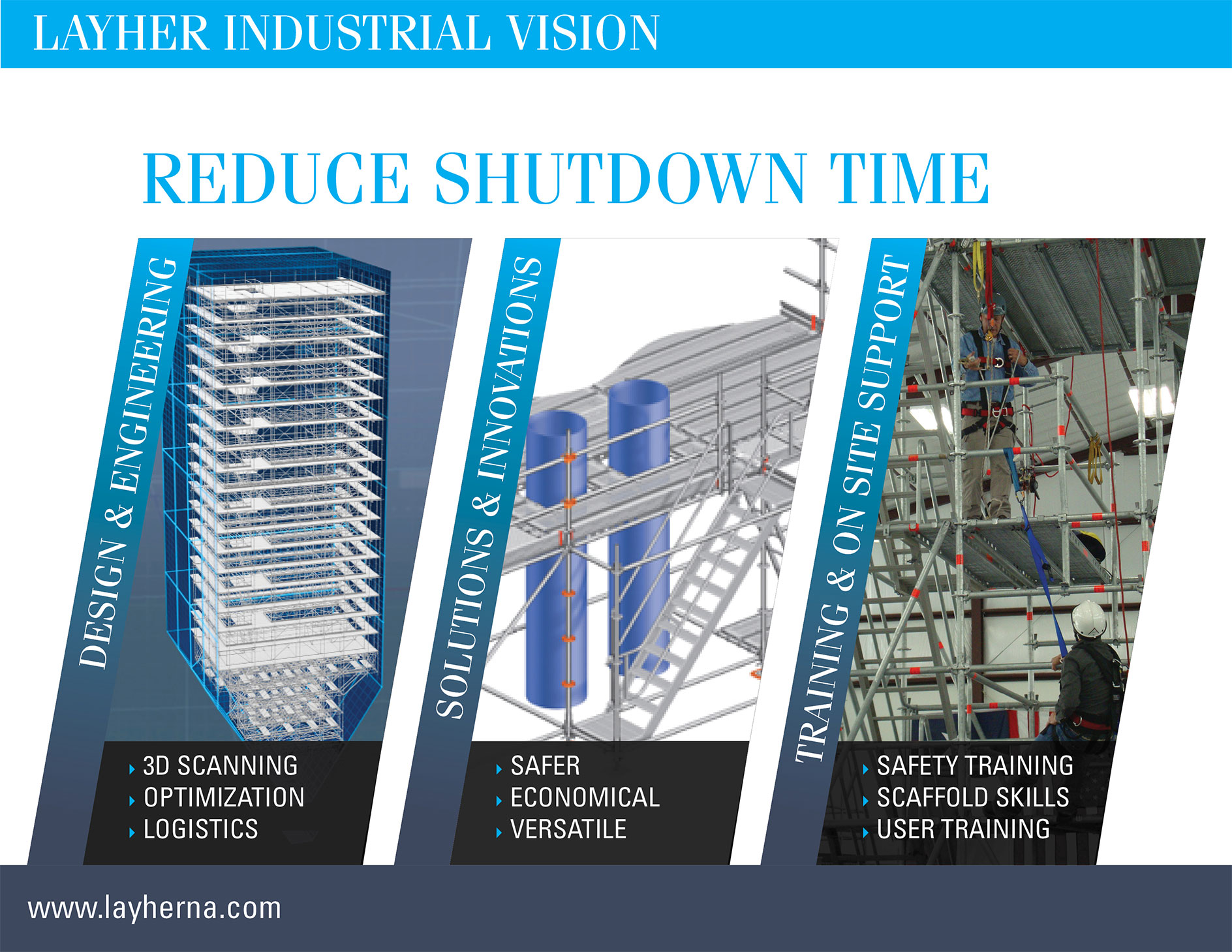

To this end, Layher uses Scaffolding Information Modeling – a design process software built to meet the requirements of industrial scaffolding. Layher SIM allows you to plan scaffolding in detail; strategize and schedule; increase safety and profitability; provide transparency and cost control; budget; simulate the construction process; conduct feasibility studies; and implement accordingly.

Furthermore, Layher offers on-site, in-house, and remote training options to meet your needs. Training addresses safety and improvement concerns and can be structured to meet any level of expertise. Courses cover a variety of topics, from scaffolding installation to the latest innovations.

Additional on-site support provides an extra resource for critical project needs, with experts available to answer questions and ensure the project is progressing as planned. Layher engineers also work with field supervisors to ensure effective planning and logistics, reducing the likelihood of change orders.

HAS MY SCAFFOLDER DEMONSTRATED COST-SAVINGS FOR OTHER CLIENTS?

Lastly, don’t be afraid to ask for references. Project-proven contractors are in ample supply of those willing to sing their praises and verify cost savings. Take advantage of the opportunity to find out what they did for others and how they can do the same for you.

Because actions speak louder than words, scaffolders with access to innovation must ultimately employ it. Those with adaptable components, must demonstrate their effectiveness. Those with their clients’ best interests must show they are willing to help save them money. And those that offer support must model superior planning and logical efforts throughout all Maintenance, Startup, and Shutdown project phases.

As a plant manager, one of the best things you can do to keep operations running smoothly is get involved with scaffolding decisions. Ask questions, talk to purchasing, and engage scaffolding contractors and suppliers that you already work with or are considering. Your new-found interest in scaffolding has the potential to save your plant millions.