COMMERCIAL & INDUSTRIAL LAYHER LIGHTWEIGHT SCAFFOLDING SOLUTIONS

COMMERCIAL & INDUSTRIAL LAYHER LIGHTWEIGHT SCAFFOLDING SOLUTIONS

THE NEW GENERATION OF SCAFFOLDING – LESS WEIGHT, MORE PERFORMANCE.

THE NEW GENERATION OF SCAFFOLDING – LESS WEIGHT, MORE PERFORMANCE.

Layher has been the driving force behind scaffolding innovation for more than 60 years. In 1965, Layher SpeedyScaf® revolutionised the industry; and 1974 saw the launch of Layher Allround Scaffolding®, a modular product portfolio that took the world market by storm. But now, Layher engineers have succeeded in using high-tensile automotive steel that significantly lowers the weight of components and are introducing a new dimension in scaffolding: Layher Lightweight.

Layher Lightweight is the result of a major, multi-year R&D project with a clearly defined objective: to make scaffolding easier, safer, and more cost effective for our customers. The modular Layher Lightweight line will revolutionize the erection and dismantling of challenging scaffolding structures. The use of high-tensile steel allows reduced wall thickness, delivering a significant weight saving and higher load-bearing capacity. The result is lighter components, easier and faster erection, and lower shipment costs. The Layher Lightweight line is also compatible with conventional Layher scaffolding and can be used with existing Layher components.

THE BENEFITS OF LAYHER LIGHTWEIGHT

THE BENEFITS OF LAYHER LIGHTWEIGHT

- Lower weight

- Enhanced load-bearing capacity

- Improved safety

- Fully compatible with Layher Allround components

- Time-saving construction site erection and dismantling

- Cost savings through approximately 10% higher productivity

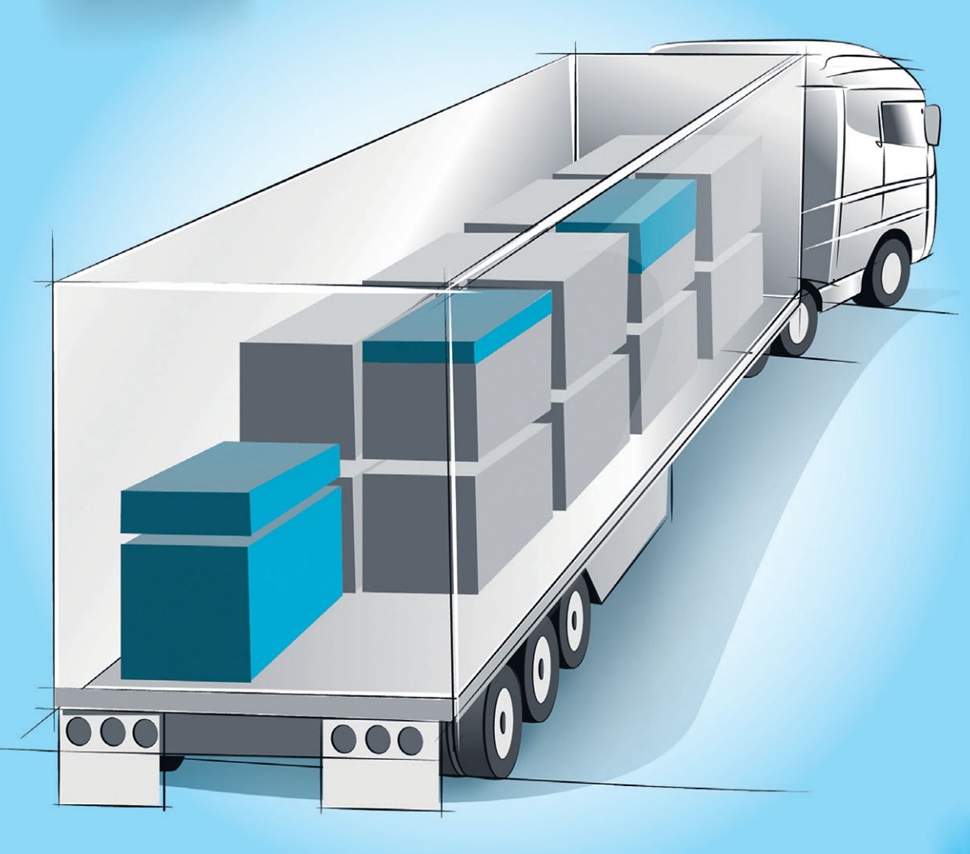

- Approximately 12% increase in truck payload by volume

FASTER ERECTION & DISMANTLING

FASTER ERECTION & DISMANTLING

SAVE WEIGHT & MONEY WITHOUT COMPROMISING STRENGTH.

Lighter is faster. Some 80% of the total cost of scaffolding is attributable to loading and unloading trucks, and to construction site erection and dismantling. Layher Lightweight’s reduced wall thickness means a greatly lowered component weight and up to 10% faster erection of birdcage structures.

LOWER SHIPMENT COSTS – GET MORE ON YOUR TRUCK WITH LIGHTER LOADS.

A truck‘s maximum permissible payload is determined by weight, not volume. Therefore Layher Lightweight components mean additional savings when it comes to shipping ledgers and standards to and from the construction site. For example, with a truck plated to carry a maximum load of 23 metric tons, you could transport approximately 6,400 m3 of birdcage scaffolding. With Layher Lightweight components, that figure rises to some 7,200 m3. That is 12 % more. That translates into fuel and manpower savings, and is better for the environment.

SAVE WEIGHT & MONEY WITHOUT COMPROMISING STRENGTH.

Lighter is faster. Some 80% of the total cost of scaffolding is attributable to loading and unloading trucks, and to construction site erection and dismantling. Layher Lightweight’s reduced wall thickness means a greatly lowered component weight and up to 10% faster erection of birdcage structures.

LOWER SHIPMENT COSTS – GET MORE ON YOUR TRUCK WITH LIGHTER LOADS.

A truck‘s maximum permissible payload is determined by weight, not volume. Therefore Layher Lightweight components mean additional savings when it comes to shipping ledgers and standards to and from the construction site. For example, with a truck plated to carry a maximum load of 23 metric tons, you could transport approximately 6,400 m3 of birdcage scaffolding. With Layher Lightweight components, that figure rises to some 7,200 m3. That is 12 % more. That translates into fuel and manpower savings, and is better for the environment.

LAYHER LIGHTWEIGHT – THE NEXT DIMENSION IN SCAFFOLDING

LAYHER LIGHTWEIGHT – THE NEXT DIMENSION IN SCAFFOLDING

Profitability and safety aren’t contradictions at Layher.

On the contrary, they’re what drive us: new materials, new production processes and design improvements to make our systems lighter, faster, stronger. And so even more economical.

Profitability and safety aren’t contradictions at Layher.

On the contrary, they’re what drive us: new materials, new production processes and design improvements to make our systems lighter, faster, stronger. And so even more economical.

THE LAYHER LIGHTWEIGHT PHILOSOPHY

THE LAYHER LIGHTWEIGHT PHILOSOPHY

OUR OVERRIDING PRIORITY IS OUR CUSTOMERS’ SUCCESS

To make scaffolding even more economical and even safer, Layher development engineers are constantly working on ingenious new developments. Our focus here is on the influencing factors for assembly performance, such as weight, shape and the number of components.

To achieve this, we constantly search for new materials and new production processes. Just a few additional components also continuously provide our customers with new fields of business, since the utilization of their material stocks is also a crucial economic factor. Thanks to uniform system dimensions and appropriate combination approvals, all our innovations are designed to be interchangeable with existing components of the Layher product portfolio – including our earlier product generations. This ensures investment security. The strengths of our integrated system.

OUR OVERRIDING PRIORITY IS OUR CUSTOMERS’ SUCCESS

To make scaffolding even more economical and even safer, Layher development engineers are constantly working on ingenious new developments. Our focus here is on the influencing factors for assembly performance, such as weight, shape and the number of components.

To achieve this, we constantly search for new materials and new production processes. Just a few additional components also continuously provide our customers with new fields of business, since the utilization of their material stocks is also a crucial economic factor. Thanks to uniform system dimensions and appropriate combination approvals, all our innovations are designed to be interchangeable with existing components of the Layher product portfolio – including our earlier product generations. This ensures investment security. The strengths of our integrated system.

THE RESULT: LAYHER LIGHTWEIGHT – THE NEXT DIMENSION IN SCAFFOLDING

THE RESULT: LAYHER LIGHTWEIGHT – THE NEXT DIMENSION IN SCAFFOLDING

Assembly, dismantling and transport make up 80 % of scaffolding service costs. Studies have clearly shown that by reducing component weight, our customers can considerably enhance both their assembly and dismantling performances and use their transport capacities more efficiently. This is where our new Layher Lightweight philosophy comes to the fore.

By using higherstrength steel grades, new production processes and design improvements, we have succeeded in minimising the weight of the basic components of our SpeedyScaf and Allround Scaffolding systems – without reducing their high load capacities.

Assembly speed can be increased up to 10%, transport capacity up to 12%. As part of our integrated system, the lightweight products can also be combined with our previous product versions. Combination approvals are of course available.

LIGHTWEIGHT COMPONENTS CAN BE IDENTIFIED BY THE LUMINOUS RED LABEL WITH LAYHER BANDEROLE AND THE LAYHER LIGHTWEIGHT SEAL.

LIGHTWEIGHT COMPONENTS CAN BE IDENTIFIED BY THE LUMINOUS RED LABEL WITH LAYHER BANDEROLE AND THE LAYHER LIGHTWEIGHT SEAL.

LAYHER LIGHTWEIGT – MORE THAN JUST WEIGHT

LAYHER LIGHTWEIGT – MORE THAN JUST WEIGHT

Contact us for the Layher Lightweight brochure for more detailed product information and specifications including:

- The new auto lock function & redesigned wedge-head

- Increased headroom with Allround reinforced bridging ledgers LW

- Reduced shipping costs with Layher Lightweight components

- Allround Lightweight product specifications

- Weight comparisons: Allround Lightweight vs. Allround Standard

- SpeedyScaf Lightweight product specifications

LAYHER ALLROUND LIGHTWEIGHT

LAYHER ALLROUND LIGHTWEIGHT

The lighter components increase the speed of assembly and also transport capacities – that saves real money.

LAYHER SPEEDYSCAF LIGHTWEIGHT

LAYHER SPEEDYSCAF LIGHTWEIGHT

A worthwhile investment. Faster assembly, lower transport weight, same load-bearing capacity. Less weight for more performance.

LIVE ASSEMBLY OF LAYHER ALLROUND LIGHTWEIGHT

LIVE ASSEMBLY OF LAYHER ALLROUND LIGHTWEIGHT

Layher Lightweight is the result of a major, multi-year R&D project with a clearly defined objective: to make scaffolding easier, safer, and more cost effective.