ALUMINIUM TWIXBEAM

Layher Commercial & Industrial

Aluminium Twixbeam Solutions

LOW WEIGHT, EASY DISMANTLING

AND HIGH STRENGTH

The Layher Aluminum TwixBeam is a versatile beam solution for scaffolding and shoring applications. Made from two bolted aluminum U-sections, it offers high strength while remaining lightweight for easy handling.

This multifunctional beam is used in various applications, including wide-span work platforms, support beams, suspended scaffolding, and projecting structures. Available in different lengths, the TwixBeam can be adapted to project requirements.

ALUMINUM TWIXBEAM

The Multifunctional Beam for Scaffolding Construction

The Aluminum TwixBeam is a multifunctional system solution, with possible uses from support beams, suspended scaffold-ing or projection structures, to wide-span work platforms and use as a system main beam. So the TwixBeam is the multifunctional aluminum beam for scaffolding and shoring construction.

THE TWIXBEAM IN SCAFFOLDING CONSTRUCTION

The high-strength, multifunctional aluminum TwixBeam from Layher—consisting of two bolted aluminum U-sections—has a wide range of possible uses as wide-span work platforms, support beams, suspended scaffolding, or projecting structures. It is characterized by high load-bearing capacity yet low weight.

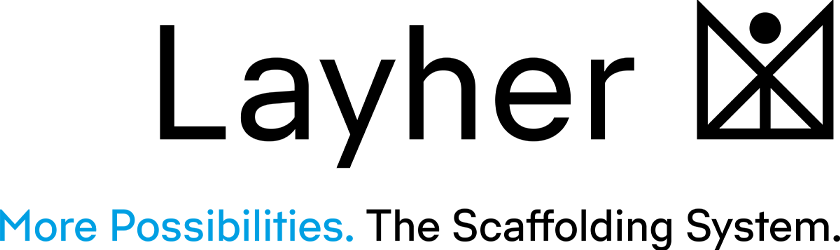

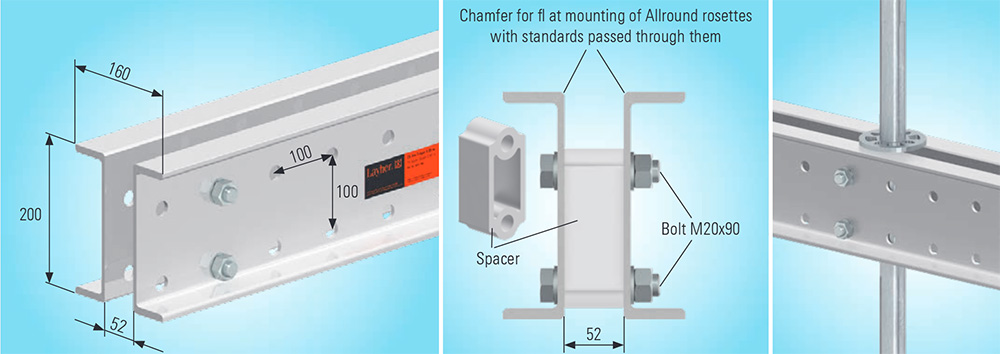

Many matching expansion parts are available for the aluminum TwixBeam: The swiveling spindle is inserted into the intermediate area of the beam and pinned in place. It can be used as a head jack or base plate. Standard or suspended structures can be built by passing through an Allround standard or the swiveling spindle. The spindle strut (patent pending) permits stiffening or bracing of various structures – it can transmit tensile and compressive forces. The beam connector and insertion beam complete the system for flexible adaptability to all site conditions and contours.

Aluminum as the material ensures low weight in the beam. The bolted structure permits dismantling of the beam for different applications while ensuring that the material retains its maximum loading capacities and is not weakened by welding.

GROUND ANCHORING

Instead of using ballast, scaffolding structures with the TwixBeam can also be anchored in the ground.

- Anchoring in the ground is achieved using threaded rods and matching plate nuts attached by others

- This leads to enormous logistic benefits, since ballast weights do not have to be transported to the site and moved around there.

- The beam can, thanks to its bolted design, easily be dismantled into its individual parts and then reassembled. This permits subsequent attachment too.

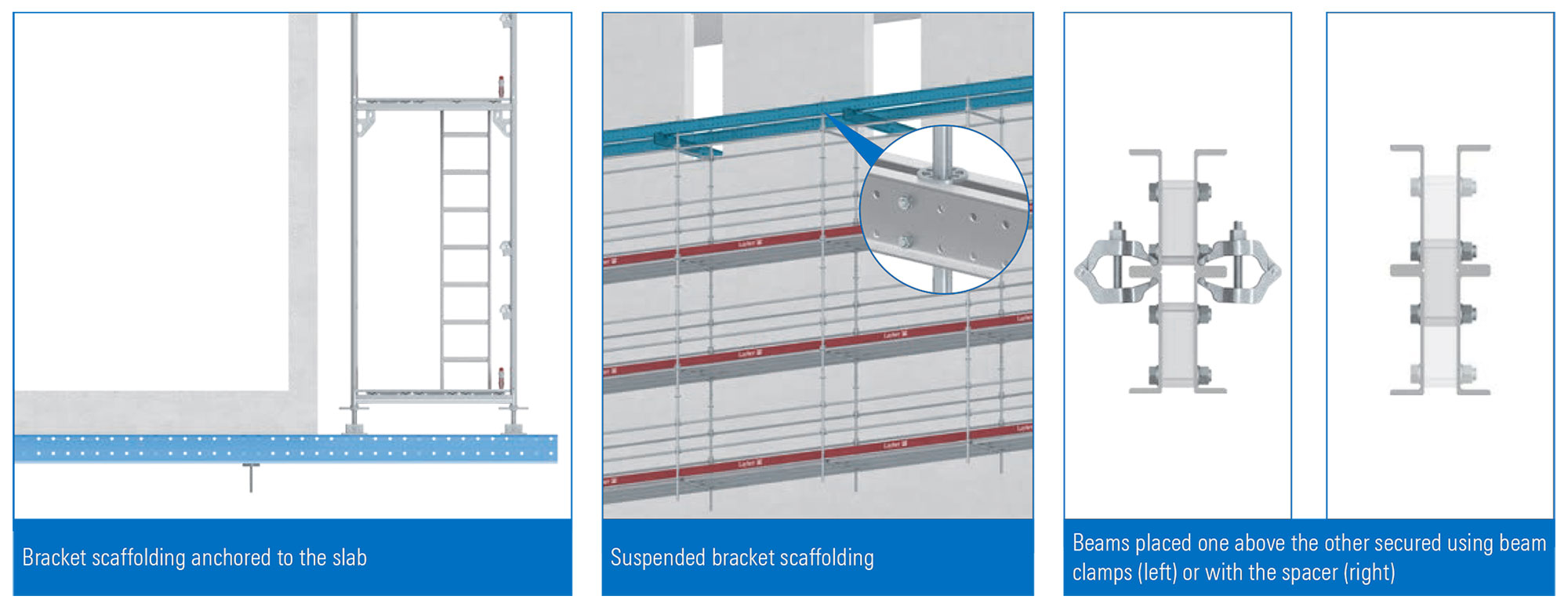

BRACKET APPLICATIONS

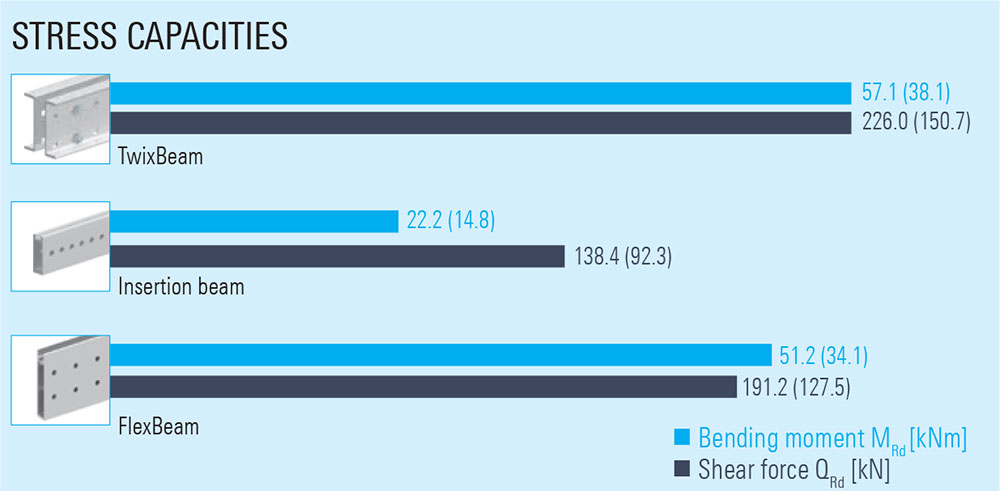

Where the ground is not sufficiently load-bearing, or where particularly material-saving scaffolding structures have to be built, the TwixBeam permits standard or suspended scaffolding to be assembled.

- Standard structures can be built with the Allround standards passed through or with the swivelling TwixBeam spindle.

- Projecting structures in unfinished buildings can have two designs: anchored to the slab or in the ground, or braced against the slab.

- To provide grid platform structures, the TwixBeams can be mounted one above the other. Connection is by beam clamps

- To increase the loading capacity, the beams can also be mounted one above the other in the same direction. They are secured using beam clamps or by an offset arrangement of the spacer.

The Benefits for Scaffolding Construction

- Low-weight, easily dismantled and high-strength aluminum beam – particularly useful when passing material through narrow manholes.

- Bracket applications and bracing structures achievable within the system.

- High variability thanks to the insertion beam and combination with the aluminum FlexBeam.

- Investments protected thanks to weather resistance and frequent reusability.

- Easy angle adjustment using swivelling spindle.

The benefits for shoring construction

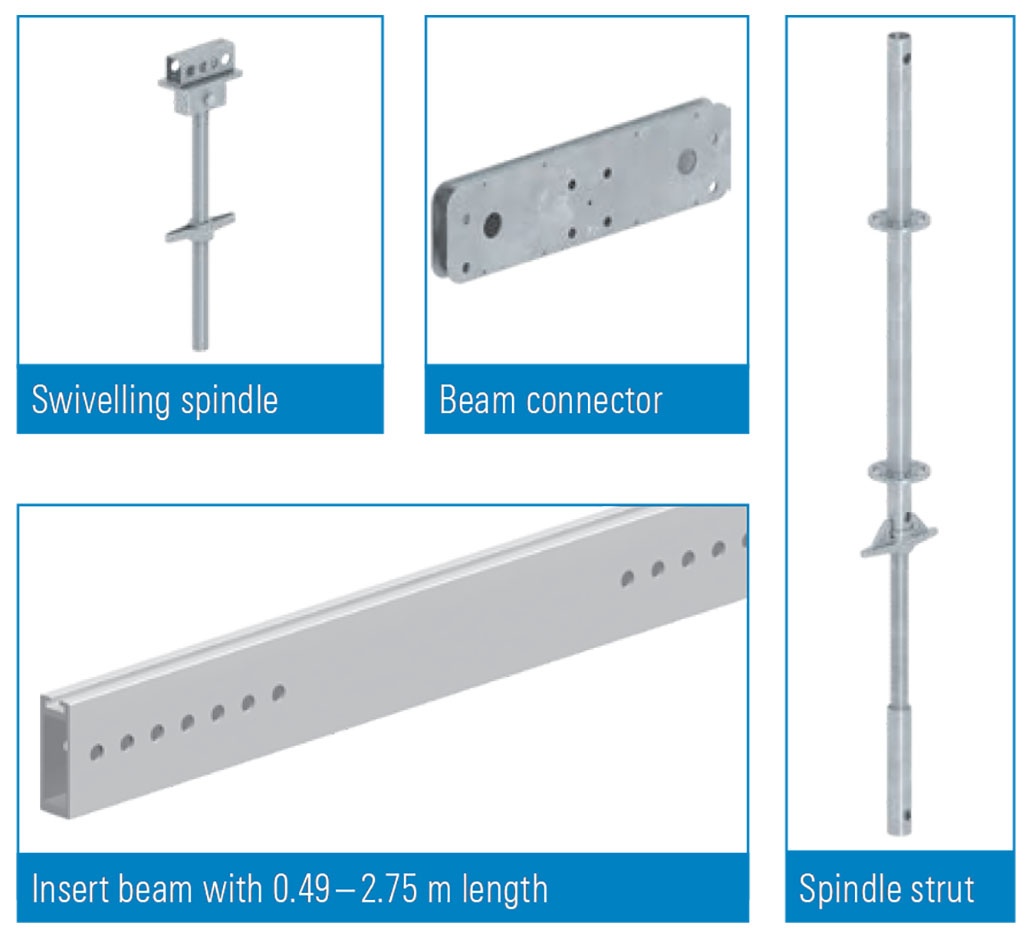

- Cost reduction from optimisation of the shoring structure, due to considerably higher bending and shear load capacities when compared with H-20 beams: less material plus shorter assembly and dismantling times saves on costs.

- System main beam matching Shoring TG 60 for all bay lengths: Planning and design work for beam joints, edge adjustments and expensive cutting to size are no longer needed.

- System main beam matching Shoring TG 60 for all bay lengths: Planning and design work for beam joints, edge adjustments and expensive cutting to size are no longer needed.

- Usable as a genuine continuous beam: transmission of tensile and compressive forces plus bending moments.

- Easy angle adjustment using swivelling spindle.

- Easy assembly and easy striking thanks to lightweight individual components – even without a crane.

- Weather-resistant and more durable in comparison with wooden beams.

Profitability and safety aren’t contradictions at Layher.

On the contrary, they’re what drive us: new materials, new production processes and design improvements to make our systems lighter, faster, stronger. And so even more economical.