SUPERIOR SCAFFOLDING

SUPERIOR SCAFFOLDING

Layher sets the standard as the leading scaffolding manufacturer in North America.

Petrochemical. Energy. Pulp and Paper. Manufacturing. Construction.

YOUR SUCCESS IS OUR PRIORITY

Increased Profits. Improved Safety. Inspired Efficiency

LAYHER: COMMITTED TO YOUR FINANCIAL SUCCESS.

How Choosing Layher Pays Off Company-Wide.

Whether you’re a manager, safety leader, engineer, or purchaser, the true cost of scaffolding includes indirect costs to productivity and other consequential expenses like extended downtime and potential threats to worker health and safety.

MANAGEMENT

If you’re overseeing a rebounding operation, you may be tempted to go with the lowest bid, but it’s sure to cost you down the line. High-quality scaffolding is an investment with long-term savings and positive effects across teams.

- Consumables: Inferior scaffolding requires the additional purchase of consumables. Layher systems are meticulously planned with all-inclusive metal parts that don’t rely on additional purchases.

- Custom parts: Advanced scaffolding systems reduce or eliminate the need for nontraditional parts with fully interlocking components. If you find yourself in need of something specific, start with Layher’s database of over 15,000 drawings.

- Change orders: Change orders drive up costs and waste money as a result of poor planning. Avoid them with Layher’s engineering team and advanced technology, LayPLAN CAD, which outputs 3D drawings, 5D models, and virtual walk-throughs that eliminate the unexpected.

- Scaffolding: Not all scaffolding is created equal. Layher considers petrochemical, energy, manufacturing, and pulp and paper applications for every Allround scaffolding component, making it the most versatile scaffolding on the market.

SAFETY

If you’re a health and safety manager, you know the dangers of cutting corners at the expense of safety. A one-time Layher scaffolding purchase is more than a material line item; it’s a precaution that prioritizes worker safety.

- Consumables: All-metal parts reduce the need for additional field hours that would be otherwise engaged in cutting wood for corners, planks, and toe boards. This translates to reduced risk to worker safety and elimination of fire hazards.

- Custom parts: The safety of any scaffolding product starts with quality materials. A cheaper product often introduces the possibility of bad welding, rust, and corrosion. Layher parts start with high-quality materials and singular pieces that resist deterioration and breakage.

- Change orders: The same technology Layher uses to reduce change orders can be shared with safety officers to improve planning, inform worksite meetings, and identify ways to reduce risk. Perform virtual walkthroughs for training and reduce risks of OSHA incidents.

- Scaffolding: Allround safety features include a locking wedge to secure components, a locking pin to prevent wind lift, and extra board perforations to allow pass-through. Hatch decks with inside ladders, stairway landings, and handrails reduce fall risks.

ENGINEERING

Engineering never needs convincing when it comes to Layher. All it takes is a single use of Layher scaffolding, specialized software, and engineering support to become a true believer.

- Consumables: Users report a 10 % reduction in labor costs with Layher’s custom software, LayPLAN CAD. This AutoCAD plugin allows scaffolders to see the build ahead of time and design around potential obstacles.

- Custom parts: Layher’s database includes over 15,000 product drawings that provide a starting point for clients to modify. There is hardly an application that Layher engineers haven’t seen, and they are available to help in the most challenging situations.

- Change orders: Change orders can translate to thousands in lost revenue during shutdown. Avoid surprises and excessive outages by working with Layher to plan every shutdown in detail. This makes for a seamless transition between design and purchasing.

- Scaffolding: Layher Lightweight, high-tensile steel products come in over 4,000 parts to make engineering design dreams come true. Get the job done with confidence using corrosion-protected galvanized steel and the Layher Allround.

PURCHASING

If you’re in purchasing, you may be used to asking vendors to quote by weight, but in the world of scaffolding, that’s a serious mistake. Lighter weights mean quicker transport and less effort, which conserves energy and keeps workers fresh.

- Consumables: Most purchasers keep a keen eye on shipping costs. Heavier weights, combined with poor packing, can drive up the real price. In contrast, Layher Lightweight products and space-saving packing practices reduce shipping costs so you stay on budget.

- Custom parts: Avoid excessive costs in design, material, and labor that can add up with the need for special parts. With a database of unique products made to order or modify, Layher has already made the investment so you don’t have to.

- Change orders: Perhaps no one knows the harsh reality of multiple change orders like the purchasers who see those bills pile up quickly. Mitigate change orders by avoiding weight quotes, which can vary the number of components greatly.

- Scaffolding: Vendors of heavier scaffolding take advantage of weight quotes to cast less-desirable scaffolding in a more favorable light. Don’t be fooled. Coordinate with engineering to provide vendors with a planned design, and request quotes by the job an accurate comparison that includes shipping estimates.

LAYHER: COMMITTED TO YOUR FINANCIAL SUCCESS.

How Choosing Layher Pays Off Company-Wide.

Whether you’re a manager, safety leader, engineer, or purchaser, the true cost of scaffolding includes indirect costs to productivity and other consequential expenses like extended downtime and potential threats to worker health and safety.

MANAGEMENT

If you’re overseeing a rebounding operation, you may be tempted to go with the lowest bid, but it’s sure to cost you down the line. High-quality scaffolding is an investment with long-term savings and positive effects across teams.

- Consumables: Inferior scaffolding requires the additional purchase of consumables. Layher systems are meticulously planned with all-inclusive metal parts that don’t rely on additional purchases.

- Custom parts: Advanced scaffolding systems reduce or eliminate the need for nontraditional parts with fully interlocking components. If you find yourself in need of something specific, start with Layher’s database of over 15,000 drawings.

- Change orders: Change orders drive up costs and waste money as a result of poor planning. Avoid them with Layher’s engineering team and advanced technology, LayPLAN CAD, which outputs 3D drawings, 5D models, and virtual walk-throughs that eliminate the unexpected.

- Scaffolding: Not all scaffolding is created equal. Layher considers petrochemical, energy, manufacturing, and pulp and paper applications for every Allround scaffolding component, making it the most versatile scaffolding on the market.

SAFETY

If you’re a health and safety manager, you know the dangers of cutting corners at the expense of safety. A one-time Layher scaffolding purchase is more than a material line item; it’s a precaution that prioritizes worker safety.

- Consumables: All-metal parts reduce the need for additional field hours that would be otherwise engaged in cutting wood for corners, planks, and toe boards. This translates to reduced risk to worker safety and elimination of fire hazards.

- Custom parts: The safety of any scaffolding product starts with quality materials. A cheaper product often introduces the possibility of bad welding, rust, and corrosion. Layher parts start with high-quality materials and singular pieces that resist deterioration and breakage.

- Change orders: The same technology Layher uses to reduce change orders can be shared with safety officers to improve planning, inform worksite meetings, and identify ways to reduce risk. Perform virtual walkthroughs for training and reduce risks of OSHA incidents.

- Scaffolding: Allround safety features include a locking wedge to secure components, a locking pin to prevent wind lift, and extra board perforations to allow pass-through. Hatch decks with inside ladders, stairway landings, and handrails reduce fall risks.

ENGINEERING

Engineering never needs convincing when it comes to Layher. All it takes is a single use of Layher scaffolding, specialized software, and engineering support to become a true believer.

- Consumables: Users report a 10 % reduction in labor costs with Layher’s custom software, LayPLAN CAD. This AutoCAD plugin allows scaffolders to see the build ahead of time and design around potential obstacles.

- Custom parts: Layher’s database includes over 15,000 product drawings that provide a starting point for clients to modify. There is hardly an application that Layher engineers haven’t seen, and they are available to help in the most challenging situations.

- Change orders: Change orders can translate to thousands in lost revenue during shutdown. Avoid surprises and excessive outages by working with Layher to plan every shutdown in detail. This makes for a seamless transition between design and purchasing.

- Scaffolding: Layher Lightweight, high-tensile steel products come in over 4,000 parts to make engineering design dreams come true. Get the job done with confidence using corrosion-protected galvanized steel and the Layher Allround.

PURCHASING

If you’re in purchasing, you may be used to asking vendors to quote by weight, but in the world of scaffolding, that’s a serious mistake. Lighter weights mean quicker transport and less effort, which conserves energy and keeps workers fresh.

- Consumables: Most purchasers keep a keen eye on shipping costs. Heavier weights, combined with poor packing, can drive up the real price. In contrast, Layher Lightweight products and space-saving packing practices reduce shipping costs so you stay on budget.

- Custom parts: Avoid excessive costs in design, material, and labor that can add up with the need for special parts. With a database of unique products made to order or modify, Layher has already made the investment so you don’t have to.

- Change orders: Perhaps no one knows the harsh reality of multiple change orders like the purchasers who see those bills pile up quickly. Mitigate change orders by avoiding weight quotes, which can vary the number of components greatly.

- Scaffolding: Vendors of heavier scaffolding take advantage of weight quotes to cast less-desirable scaffolding in a more favorable light. Don’t be fooled. Coordinate with engineering to provide vendors with a planned design, and request quotes by the job an accurate comparison that includes shipping estimates.

YOUR TRUSTED PARTNER

Specialized projects call for a specialized solutions team.

ENGINEERING SUPPORT & EXPERT TRAINING

Layher engineering support provides planning, plan evaluation, and scaffold engineering analysis to meet your most challenging requirements. Client-tailored training in basic, advanced, and expert to meet your needs.

Sign up for LayPLAN scaffolding planning software and learn more here.

ALLROUND SCAFFOLDING

The Layher Allround is the industry standard for modular scaffolding, offering unbeatable adaptability, flexibility, and lightweight usability. It is the scaffolding of choice for industrial facilities, chemical plants, power stations, refineries, and construction sites world-wide.

Ingenious. Strong. No limits. In steel and aluminum – it’s the original one.

- The most versatile scaffolding on the market.

- Rapid, bolt-free assembly with a safer locking wedge and up to 8 connections.

- All-inclusive metal parts reduce fire risk and eliminate the need for additional purchases of consumables like wood, nails, and tape.

- Team training available in Allround basic, advanced, and expert tailored to your needs.

KEDER XL ROOF SYSTEM

The Layher Keder XL Roof System is a cost-effective, complete solution for spanning small and medium-sized gaps. Choose the Keder XL Roof system to provide weather protection in lightweight, attractive design without the need for a crane. Available as a double-pitch, mono-pitch, or asymmetrical roof for use in refurbishment work or to protect stage areas. Mobile configuration facilitates rolling roof option.

- Bridge small to moderate gaps. Option to complete enclosure using Layher Protect Panels.

- Lightweight aluminum parts make for quick assembly and allow rolling roof option.

- Fully compatible with SpeedyScaf and Allround Scaffolding Systems.

CASSETTE ROOF SYSTEM

The Layher Cassette Roof System is adaptable and rugged for spanning expansive gaps and withstanding heavier loads, providing enormously stable and versatile interim weather protection. Strong enough to walk on, the Layher Cassette Roof scaffolding system can be easily dismantled to allow material drop and includes translucent components that provide illumination.

- Bridge large gaps of up to 89 feet, with the ability to open for material drop in.

- Can be expanded into a complete enclosure using Layher Protect Panels.

- Compatible with all Layher scaffolding systems.

PROTECT PANELS

Layher Protect System Panels attach to scaffolding systems to meet your need for maximum protection. Use during asbestos removal, sandblasting work, or to protect workers or commuters from work site noise or weather. For use with SpeedyScaf and Allround Scaffolding systems, this unique protective system can open up new business ventures or extend the reach of your current operation.

- Panels fitted with rubber seals create a weather-resistant, positive pressure system and provide a barrier for hazardous materials.

- Available in clear or opaque models to allow transparency or privacy while allowing natural light.

- Operate year round with water-resistant panels that protect workers from inclement weather.

- Incorporate door panels for controlled access.

STAIRWAYS & ACCESS

Layher offers a full range of stairway solutions for temporary access on construction sites or for public use, and a complete selection of other special application access solutions. All Layher stair and access systems are OSHA and/or IBC compliant, with high load capacity, fast & easy setup, and maximum flexibility.

- Construction Access Stairs – For the jobsite. May be constructed as freestanding or adjoining tower with stairs in parallel or opposite directions. Choose these for quick assembly and ample transport of materials with maximum access along stairways to continue work.

- Construction Access Stairs (Heavy Duty) — For the jobsite. Our most utilized stringer access stair. Constructed with the Layher Allround® arranged in a 10-step flow. Choose for comfortable transport of workers and material with ample room.

- Public Access Stairs — For public access. Constructed using standard Layher Allround® components, this option includes gap covers and child safety features in compliance with IBC codes. Choose for public road crossings, pedestrian stairways, or public emergency access.

- ADA-Compliant Ramps – For public access. Layher Allround stair components, vertical guardrail panels, and Layher Public Access system handrails come together to create temporary ramps.

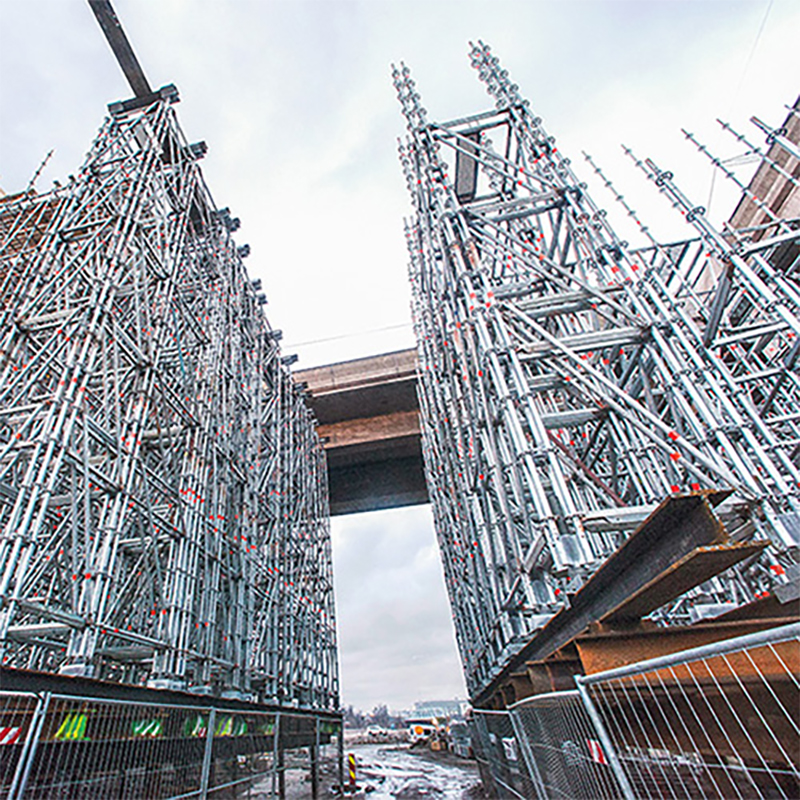

SHORING

The Layher Allround makes an ideal shoring and propping system by combining four Allround standards to achieve a high load-bearing capacity. Combine the Layher Allround with smart engineering to avoid the high cost of shoring rental and save money.

- Use Layher Allround as shoring to support heavy loads.

- Variable spacing for standards accommodates designs matched for intended weight.

- Avoid the high cost of shoring rental when you construct Layher Allround in smart design.

Why Choose Layher Scaffolding Systems

Layher is the world’s largest producer and leading industry innovator of high quality, integrated, modular scaffolding systems. Layher continues to pace the industry with product development and engineering advances for over 75 years. Layher products and innovations in scaffolding technology define quality, performance, efficiency, safety, and product innovation in modern scaffolding.

TOUGH JOB SITE? NOT FOR LAYHER.

Layher scaffolding and support provides a solution to every challenge.

LAYHER, YOUR PARTNER IN SUCCESS

From planning to implementation, we’re here to help.