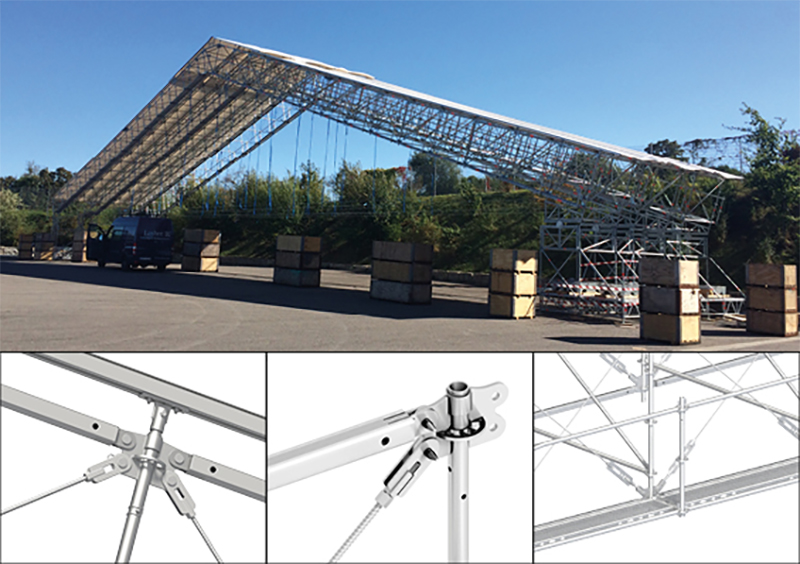

LAYHER COMMERCIAL & INDUSTRIAL ALLROUND FW ROOF SOLUTIONS

LAYHER COMMERCIAL & INDUSTRIAL ALLROUND FW ROOF SOLUTIONS

THE ALLROUND FW ROOF

The Allround FW System can be used for roof structures of temporary weather protection in addition to many solutions, such as bridging or support beams. Taking into account requirements to cope with local conditions, such as strong winds or heavy snow.

- Allround FW System with large static height allows large roof widths depending on the local weather conditions.

- Thanks to the many flexible applications for weatherproof roofs, bridgings and support beams, the Allround FW System can be used frequently.

- With only 3 additional components for Allround Scaffolding, the FW System can be mounted and integrated into Allround structures without any offset. The components are located on the system axes in all three directions.

The Allround FW System can also be used for roof structures of temporary weather protection in addition to many solutions, such as bridging or support beams.