All | The Layher Advantage | Success Stories | In the News

Increased Profits, Improved Safety, Developed Efficiency

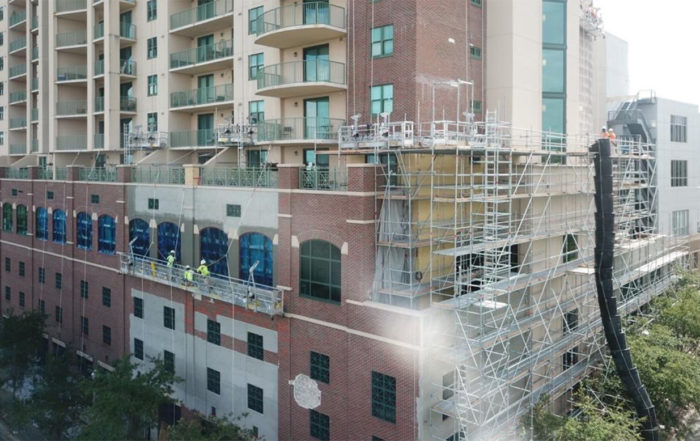

SCAFFOLD SYSTEMS

ACCESS SYSTEMS

INDUSTRIAL SCAFFOLDING

PROTECTIVE SYSTEMS

SHORING

ENGINEERING, TRAINING, SUPPORT SERVICES

THE LAYHER ADVANTAGE

RESOURCES & MORE

LAYHER NORTH AMERICA

Layher USA

Tel: 713.947.1444

Tel: 866.300.0904

8225 Hansen Road

Houston, TX 77075

Layher Canada

Tel: 866.300.0904

Tel: 780.986.9633

6207 39th Street

Leduc, AB T9E 0Z3

INTERESTING LINKS

Watch our YouTube channel to learn more about Layher Scaffold Systems.

SCAFFOLD SYSTEMS

ACCESS SYSTEMS

INDUSTRIAL SCAFFOLDING

PROTECTIVE SYSTEMS

SHORING

ENGINEERING, TRAINING, SUPPORT SERVICES

THE LAYHER ADVANTAGE

RESOURCES & MORE

LAYHER NORTH AMERICA

Layher USA

Tel: 713.947.1444

Tel: 866.300.0904

8225 Hansen Road

Houston, TX 77075

Layher Canada

Tel: 866.300.0904

Tel: 780.986.9633

6207 39th Street

Leduc, AB T9E 0Z3

INTERESTING LINKS

Watch our YouTube channel to learn more about Layher Scaffold Systems.

© Copyright - 2024 | Layher North America | All Rights Reserved | Website Design by Trubrand Marketing